King's Cross: Northern Ticket Hall development

King's Cross: Northern Ticket Hall development

A London icon gets a new lease of life

ToughGlaze supplied more than 3,000m² of heat-soaked glass for the ambitious Northern Ticket Hall development at Kings Cross. Discover how we helped keep the project on track.

How it started

A true capital investment.

King's Cross station was once a faded jewel. As the world's first subway station, it had ushered in a new age of public transportation. But by the 1990s, its glory days were long gone.

That all began to change in 1996 when the decision was made to move channel tunnel train services to nearby St Pancras. Then, in 2006, the new Western Ticket Hall was opened at Kings Cross. This game-changing development rejuvenated the historic station and provided a direct link to the newly christened St Pancras International.

The jewel was shining again – but even grander plans were afoot. The station was to be expanded again with another ticket hall, projected to cost £250 million.

The Northern Ticket Hall would complete the station's transformation and rebirth. It would drastically boost capacity, improve passenger wayfinding and give London a station that's fit for the world stage.

But it wouldn't be easy.

What happened next

A job for the best in class – and the best in glass.

In 2006, construction began in earnest with design and engineering giant Arup at the helm.

Arup worked closely with UK architectural firm Allies and Morrison to bring London Underground's brief to life. And it was a tricky brief, to say the least.

The Northern Ticket Hall would, it stipulated, have to maintain its visionary appeal for 50 years. Yet this modern, forward-thinking development would also have to complement the listed buildings adjacent to it.

This called for a simple, elegant design. There would be no sharp edges or noisy details that might give away its turn-of-the-century provenance. Instead, the development would reuse period features and make judicious use of natural light. It would be a breezy, bright space – easy to navigate and easy to like.

They needed glass – and lots of it. ToughGlaze was happy to deliver.

ToughGlaze delivers

On track from start to finish.

ToughGlaze was asked to supply all the glass panels to form the extensive balustrade bordering the new St Pancras link.

But not any glass would do. King's Cross already served more passengers per year than Heathrow Airport. The glass would have to stand up to this prodigious footfall – and pose no risk to the thousands who would pass it each day.

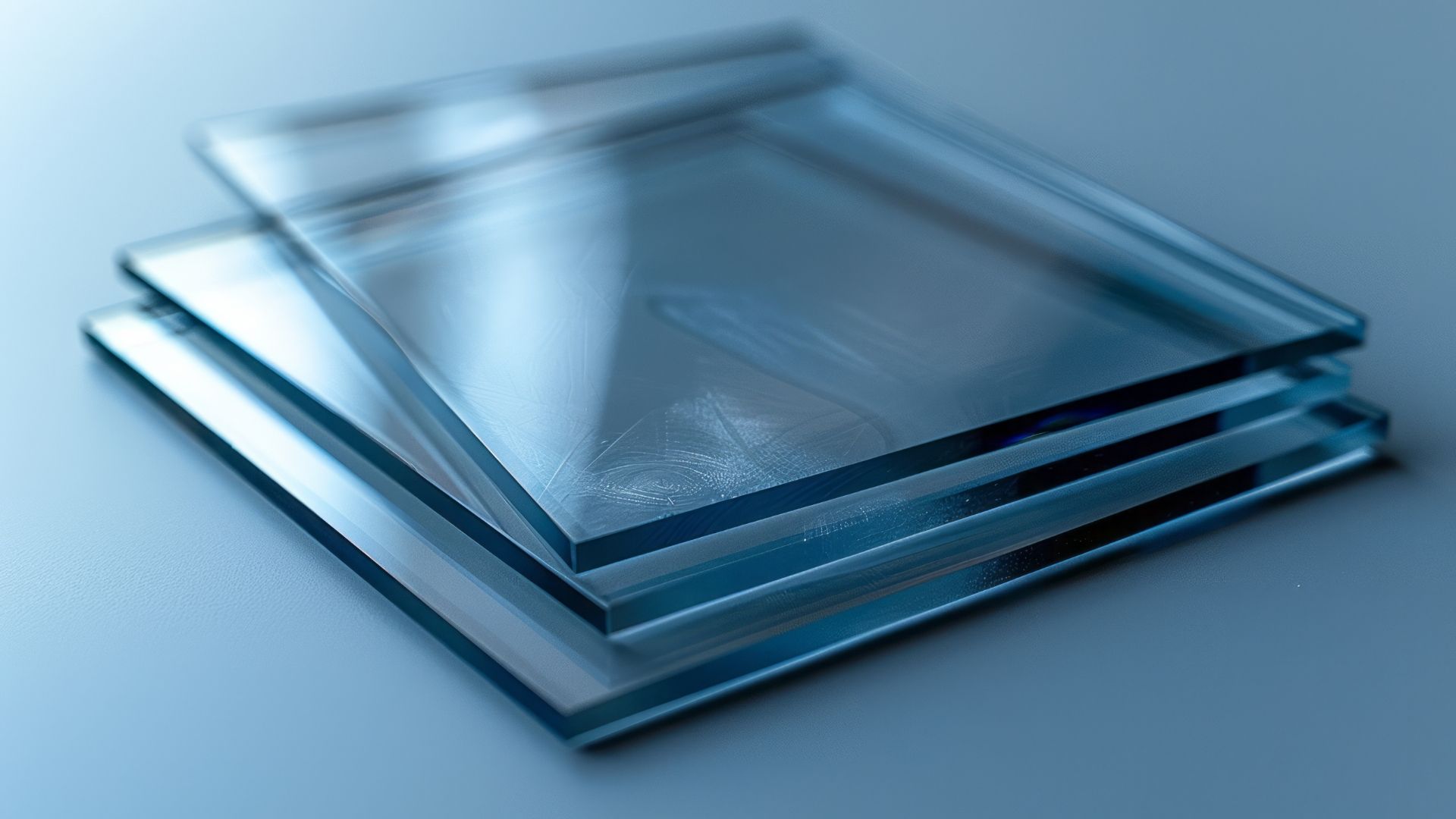

And so, ToughGlaze got to work manufacturing more than 3,000m² of 21.5mm toughened laminate. This was seriously strong glass – and every panel was heat soak tested in-house to further reduce the risk of spontaneous breakage.

Prior to toughening, many panels were also silk-screen printed. Not only would this improve aesthetic appeal by concealing building details, but it would also double down on durability. Our ultra-strong ceramic frit meant the print would last as long as the glass itself.

The Kings Cross development was a triumph of teamwork. And while our contribution was relatively small in the grand scheme of design, construction and delivery, it would prove critical to the project's overwhelming success.

For our part, we delivered all 3,000m² of glass on time and on spec. And the project as a whole was delivered under budget, saving millions of pounds while ensuring pleasant travels for millions of passengers yet to come.

The key facts

3,000m²+

Total glass coverage

2,000m²

Building size

120,000+

Daily passengers

How we did it

TG TL

Toughened laminate

We supplied more than 3,000m² of high-quality toughened and laminated glass panels.

TG SP

Screen printing

Many panels were silk-screened with our durable ceramic frit to hide structural elements.

TG HST

Heat soak testing

Heat soaking dramatically reduces the risk of spontaneous breakage – essential for a high-traffic building like King's Cross.

About ToughGlaze

Leaders in glass since 1993

Kings Cross was a big project for us. But big projects are one of our specialities.

Since 1993, we've worked with some of the biggest global names in architecture, construction and interior design. They trust us because we get the job done. We supply high-quality glass and get it where it needs to be – on time and on spec.

It's always been this way, and it always will – no matter the scale of the job.

That's thanks to our experienced team and our state-of-the-art UK facility. Only ToughGlaze can carry out all processes under one roof – from toughening to laminating to screen printing. And thanks to our proven project management capabilities, we ensure every job goes without a hitch – even with a daily throughput of 5,000m² or more.

Don't settle for missed deadlines and dropped balls. Talk to one of our experts today and keep your project on track from start to finish.

Join Our Newsletter — No Spam, Just Expert Tips and Updates for Your Next Construction Project!

| ToughGlaze LTD