Why are flat glass recycling rates so low?

Share this blog:

In the UK, flat glass recycling rates are low. Why is this – and how can the situation change? Let's find out.

Like all industries in the UK, glass is under pressure to reduce its greenhouse gas emissions. And on the face of it, it's in a stronger position than most to achieve this goal.

That's because glass can be 100% recycled. Waste glass, known as "cullet", can easily be used to produce new glass. What's more, it requires less energy to melt than primary raw materials.

So, what's the problem? Why not create a circular economy where waste glass is recycled, disposed of and recycled again?

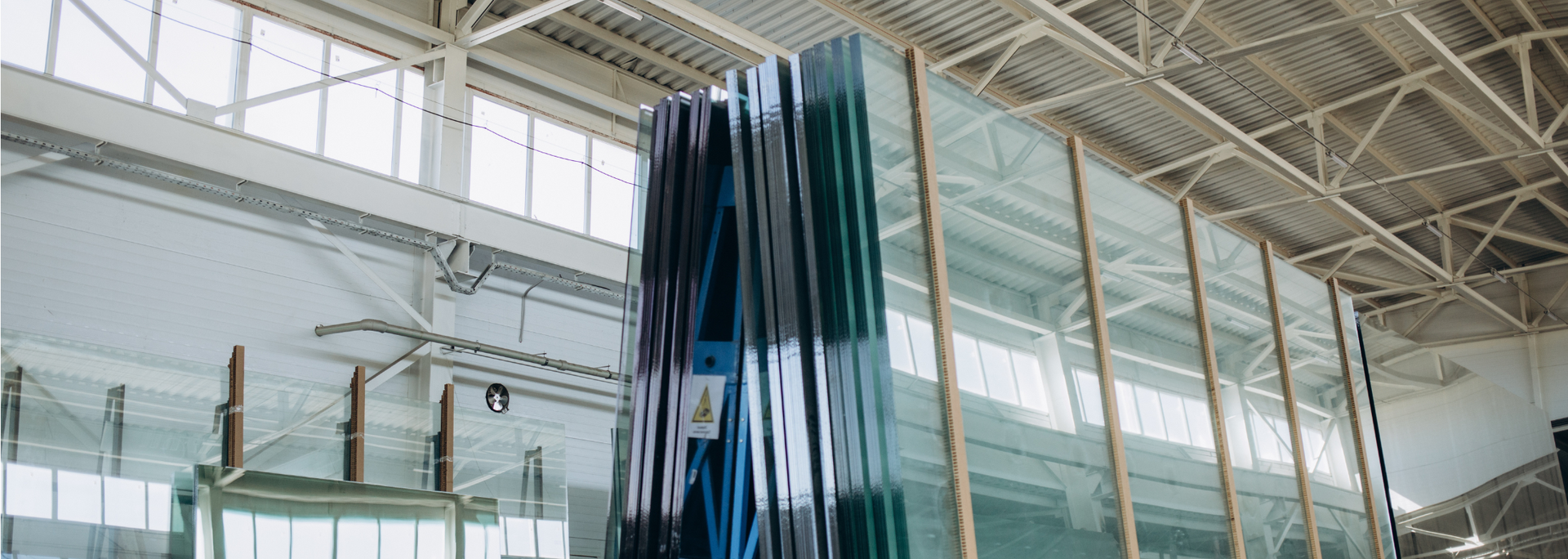

This is increasingly the case with container glass such as bottles and jars. However, the recycling rates for flat glass are surprisingly low.

The top-line reason for this is that the UK doesn't have efficient systems in place to collect, repurpose and redistribute flat glass. This results in a limited supply of cullet for manufacturers.

In this article, we take a look at this problem and the ways it can be fixed. But first, what exactly is cullet?

What is cullet?

Cullet is waste glass. It could be broken or discarded for another reason. There are three types: internal, pre-consumer and post-consumer.

Internal cullet is created during the glass manufacturing process. It primarily consists of off-cuts from edge trimming and glass discarded for quality reasons.

Pre-consumer cullet is glass that's discarded before reaching the consumer. One example of this is off-cuts from jumbo sheet glass provided to glass processors.

Both internal and pre-consumer cullet are used in the production of new glass. This is because the sorting and reprocessing tools and processes are close at hand. The problem is post-consumer cullet – the flat glass equivalent of the glass bottles and jars you put in your recycling bin.

Recycling rates are low primarily because of post-consumer cullet. In fact, only around one percent of the cullet used in glass manufacturing is post-consumer.

Recycling container glass is a relatively smooth process for consumers. But flat glass? It's a whole other story.

How does flat glass get recycled?

Like container glass, flat glass can be sorted, reprocessed and then used again. If the glass is below quality, it can be sold to alternative markets – to make aggregates, for instance, and glass beads. Flat glass that isn't collected goes to landfill.

The main barrier to flat glass recycling is the absence of efficient collection systems. In this context, "efficient" means the materials are uncontaminated and meet industry quality standards. It also means that the collection process is affordable.

Affordability is a key factor. Glass qualifies for the lower band of UK landfill tax, making it more cost-effective to send it to landfill than to collect and treat it ready for recycling.

There are also fears that post-consumer cullet is contaminated by polymers, sealants and other chemicals and that these could contaminate the new, recycled glass.

Again, this doesn't have to be a problem. Container glass recycling rates are high despite the presence of contaminants. The key problem is a lack of infrastructure.

Education and legislation

Generally speaking, people need incentives to act sustainably. If the costs associated with flat glass cullet collection and reprocessing are high, consumers and businesses are unlikely to proactively look for solutions. Could legislation be the answer?

The case of container glass is instructive. The Producer Responsibility Obligations (Packaging Waste) Regulations 1997 played a key role in improving container glass recycling rates.

Could something similar be done with flat glass? In the Netherlands, for instance, IGU fabricators pay a levy on their products, which helps fund an infrastructure of collection sites and transportation. A similar scheme in the UK could help increase overall flat glass recycling rates.

But legislation alone might not provide the answer. Consumers and businesses need to be educated about the environmental benefits of flat glass cullet.

What are the environmental benefits of flat glass cullet?

There are three key benefits to the use of flat glass cullet in the glass manufacturing process.

The first is that flat glass cullet can be sourced and processed with less energy and fewer emissions than primary raw materials.

The second is that it melts more quickly, lowering the energy needed for the furnace. By lowering furnace temperatures, an increase in the use of flat glass cullet could also reduce the demand for alternative fuel supplies.

Finally, flat glass cullet creates fewer process emissions – those greenhouse gas emissions created during the manufacturing process itself.

The benefits are clear but yet to be ingrained. It may be that climate targets and associated legislation will put pressure on the industry to create a more efficient flat glass recycling infrastructure.

What is the difference between flat glass and container glass?

Flat glass and container glass differ in both their chemical composition and their uses.

Flat glass contains more magnesium oxide and sodium oxide, whereas container glass contains more silica, calcium oxide and aluminium oxide.

Flat glass is mostly used for windows, doors and mirrors. It's also known as plate glass or sheet glass. Container glass, by contrast, is primarily used for glasses and jars.

Can toughened glass be recycled?

Toughened glass (also known as tempered glass) is a form of safety glass that's up to six times stronger than standard annealed glass.

It can be recycled but only at specialised facilities. We covered the issue in depth in our article,

"How to dispose of toughened glass".

Conclusion

Flat glass is 100% recyclable, yet post-consumer cullet recycling rates are low. This is primarily because of a lack of infrastructure, exacerbated by a lack of legislation and inconsistent messaging about the environmental benefits.

One day, the UK could have a system in place that recycles flat glass with the same efficiency as container glass. We'll be sure to keep you posted with any developments.

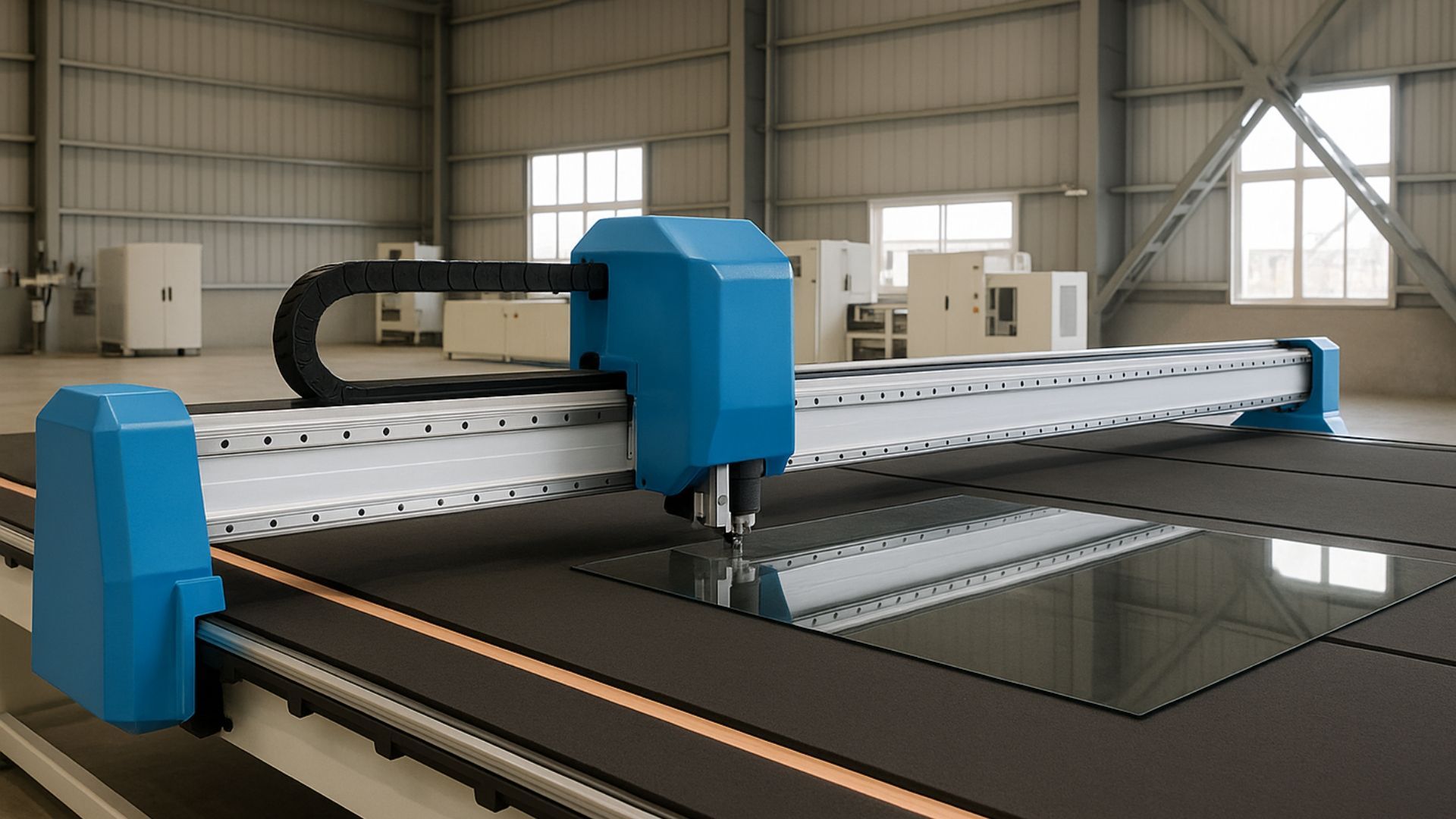

ToughGlaze is a trusted UK

commercial glass company established in 1993. Our cutting-edge facilities and extensive industry knowledge allow us to offer a huge range of glass processing options, all carried out under one roof.

Get in touch with our experts to request a quick, competitive quote.