Glass for the mining industry: why choose ToughGlaze?

Share this blog:

Looking for glass products for mining equipment and facilities? Find out why ToughGlaze is the way to go.

Every industry has to take safety seriously. But the mining industry has to take it even more seriously than most.

It's an industry that's filled with hazards – hazards that can harm mining operatives if left unchecked.

There are many ways to improve safety in the mining industry. One relates to the materials used to make mining equipment and vehicles.

It's no surprise, then, that safety glass is a key material for the mining industry. In this article, we look at its uses – and how you can choose a reputable processor to work with.

What types of glass are used in the mining industry?

The mining industry is full of hazards. For this reason, standard or annealed glass won't cut it.

There are two reasons why something sturdier is called for. First, annealed glass can break easily, leading to production stoppages. Secondly, it breaks into nasty shards that can injure workers.

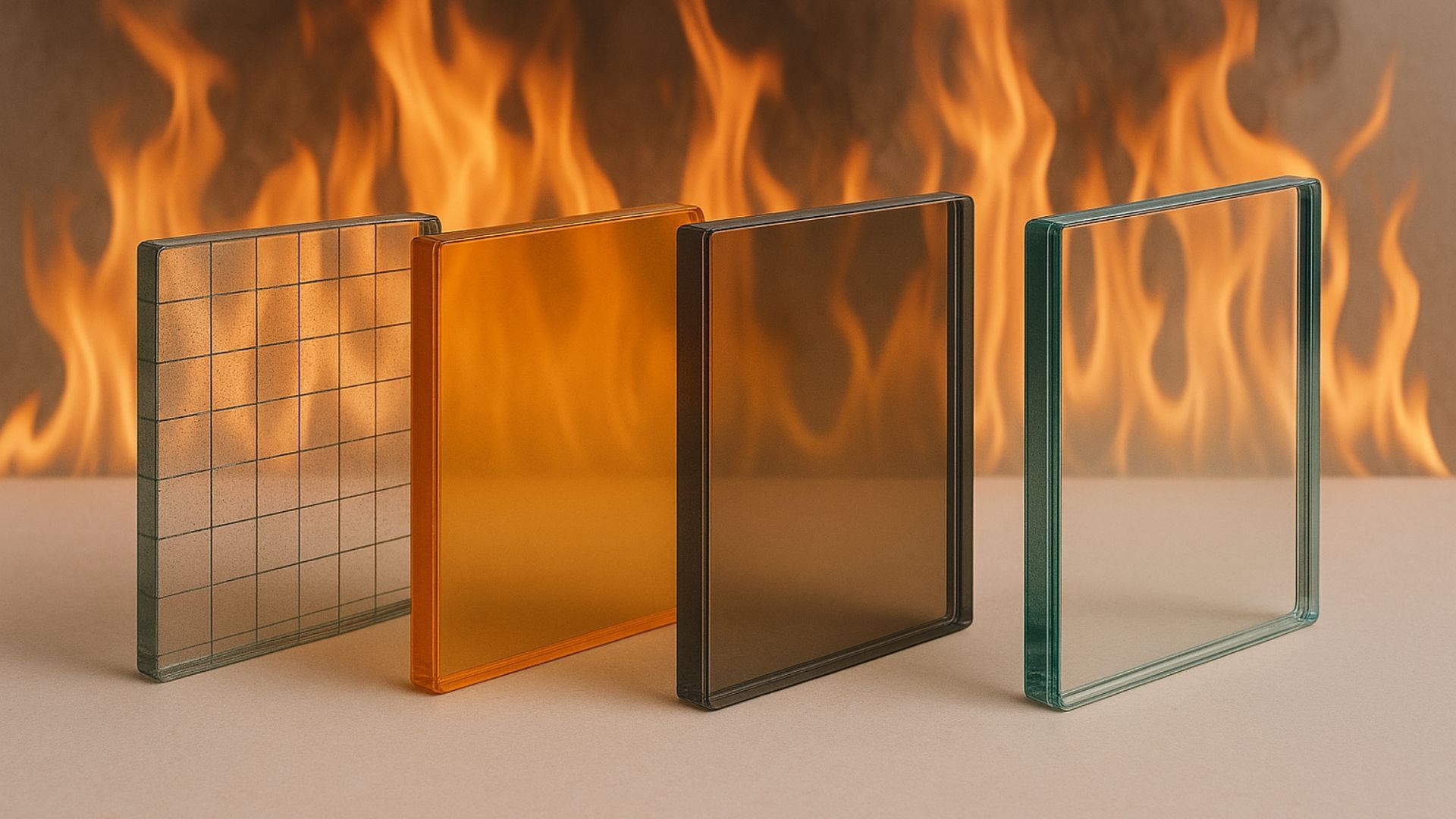

That's why most mining applications use toughened or laminated glass. These are two types of safety glass that are many times stronger than annealed glass.

They differ in a couple of ways.

Toughened glass consists of a single pane that has been heated to a high temperature and then rapidly cooled.

Laminated glass consists of two panes sandwiching a plastic interlayer.

These differences in structure lead to different levels of strength and different breakage patterns. When you break toughened glass, it shatters into harmless smithereens rather than the jagged shards left by annealed glass. But when laminated glass breaks, the glass stays in its frame. Rather than shattering, it cracks along the surface.

Toughened glass is ideal for many mining applications because of its ability to withstand temperature extremes, from the kinetic heat of machinery to the chilly depths of cold storage.

It can also withstand corrosive conditions better than standard glass. This makes it the perfect fit for environments where there's plenty of movement, noise and detritus. And when it breaks, it does so safely, reducing the chance of injury to machinery operatives.

Meanwhile, laminated glass is a fixture in earthmoving and mining equipment and vehicles. This is mainly to protect drivers in the case of a windscreen or window breakage. But it has other advantages for mining personnel.

First of all, laminated glass significantly reduces noise inside the vehicle. And secondly, it increases comfort by reflecting almost all UV rays.

These are all onsite applications. However, glass can also be used for site offices, from signage to partitions, from doors and windows to walls.

Glass has the edge over other materials in that it lets you combine an open-plan aesthetic with partitioned workspaces. Moreover, glass can easily be

etched,

printed or otherwise

decorated with company branding.

There's even

smart glass, a glass product that can switch from transparent to opaque. It's an increasingly common sight, found in planes, hotels, car sunroofs and apartments. It can also be used in offices to provide privacy on demand and a touch of class.

Glass, then, is a staple of the mining industry. The market, however, is flooded with options. How do you know which glass processor to choose?

How to choose a glass processor

When it comes to choosing a glass processor, there are a number of things to keep in mind.

First, you need a firm that stocks a wide range of products. A glass processor isn't like a high-end restaurant, where a smaller menu means a more sophisticated chef. If a firm can't provide you with laminated glass, say, or glass that's been

digitally printed, they probably don't have the skills, expertise and equipment you're looking for.

Next, you need to look for accreditations. Online reviews and word of mouth only tell you so much about a company. Accreditations provide an objective stamp of approval that tells you you're in safe hands.

In the world of glass, this means Kitemarked products and BS EN standards. Always look for these before signing off on a shipment of toughened glass.

The bottom line is that a problem with your glass supplier becomes a problem for you. Make sure you get the best materials for your mining equipment and facilities and save yourself the hassle of returning, replacing and rethinking. After all, who's got time for that?

In the mining industry, safety can never be an afterthought. That's why it's so important to get glass that's tougher than tough and built to withstand manual force, environmental pressures and accidents.

Why work with ToughGlaze?

ToughGlaze has provided a wide range of industries with glass products since 1993.

This experience is reflected in our equipment. We've got advanced equipment that can do far more than just cut glass panels to size. We can frost. We can laminate. We can make smart glass,

fire-rated glass,

security glass and more. Whatever effect or function you're after, we can realise it for you.

The last few years have seen a huge spike in supply chain disruptions. It's no exaggeration to say that these days, disruptions are no longer the exception to the rule.

This is a problem in the glass industry for one key reason. Most of the time, a single pane of glass will have been cut in one place, fired in another and treated in yet another.

If there's a weak link in the chain, you'll feel it in the form of aggravating delays. More aggravating still, the number of players involved makes it hard to know who's responsible when something goes wrong.

At ToughGlaze, we circumvent this problem by doing everything under one roof. We even deliver!

This means a quick turnaround and clear lines of communication.

In a safety-first industry like mining, good-quality materials are essential. Are you looking for high-quality

toughened or

laminated glass, cut to size? Don't hesitate to

get in touch. We'll have the materials you need on the way in no time.