Different types of glass distortion explained

Share this blog:

Why do visual distortions happen in glass? And when is it considered a fault? Get the answers in our guide.

Visual distortions in glass are a bit like those funky-tasting peanuts you sometimes find at the bottom of the bag. To a certain extent, they're expected and accepted. However, if every peanut tasted weird, you'd know something had gone wrong at the nut factory.

The ideal glass, of course, is perfectly transparent and free of visual imperfections. But the more that glass is processed, the more likely distortion will rear its ugly, bendy head. That's why toughened and heat-strengthened glass is more likely to be distorted than standard annealed glass.

A good glass processor will do everything it can to minimise these distortions – but they can never be truly eliminated.

For you, as a customer, the measure is "How much distortion?" Does the glass look a little wobbly in the wrong light or do you feel like you've wandered into a hall of mirrors? Is there one bad nut in the bag or 30 of the things?

In other words, if you see a little distortion, forgive it – it's inevitable. If, however, the glass is so distorted that it drastically diminishes its aesthetic appeal, consider writing a strongly worded letter and taking your business elsewhere.

Of course, before you complain, you need to know what to look for. In this guide, we cover four of the most common types of visual distortions and let you know what's considered acceptable – and when.

Roller-wave distortion

Roller-wave distortion manifests as a fairly consistent series of rippled lines. It's often invisible under normal circumstances and only becomes apparent when reflections appear on the glass.

Roller waves are a side effect of heat treatments, such as toughening and heat strengthening. That's because the glass enters and exits the furnace on large rollers. The glass becomes softer and more pliable as it heats, causing it to sag – ever so slightly – between the rollers.

This type of distortion is not considered a defect – it's inherent to heat-treated glass and can't be completely eliminated. However, glass processors can take steps to mitigate it by tweaking variables like heat uniformity and quenching time.

Factors like glass thickness and size can also affect the level of distortion.

The good news is that roller waves have no impact on durability. Your glass might look a little odd from certain angles, but you can rest assured that it's as strong as it needs to be.

Strain-pattern distortion

Strain-pattern distortion is, like roller-wave distortion, a side effect of the glass toughening process.

However, unlike roller waves, strain patterns can't really be mitigated. They're more or less always there – but you'd have to look hard to notice them.

What should you look for? The best description we can come up with is "translucent leopard spots". These spots appear throughout the glass, but only under certain light conditions or when viewed from specific angles.

Again, this type of distortion is not considered a defect, and there's not much you can do about it. Those leopard spots are caused by tension within the glass.

It's this tension that gives toughened glass its impressive strength. Without the spots, it would be plain old, easily breakable annealed glass.

Newton's rings

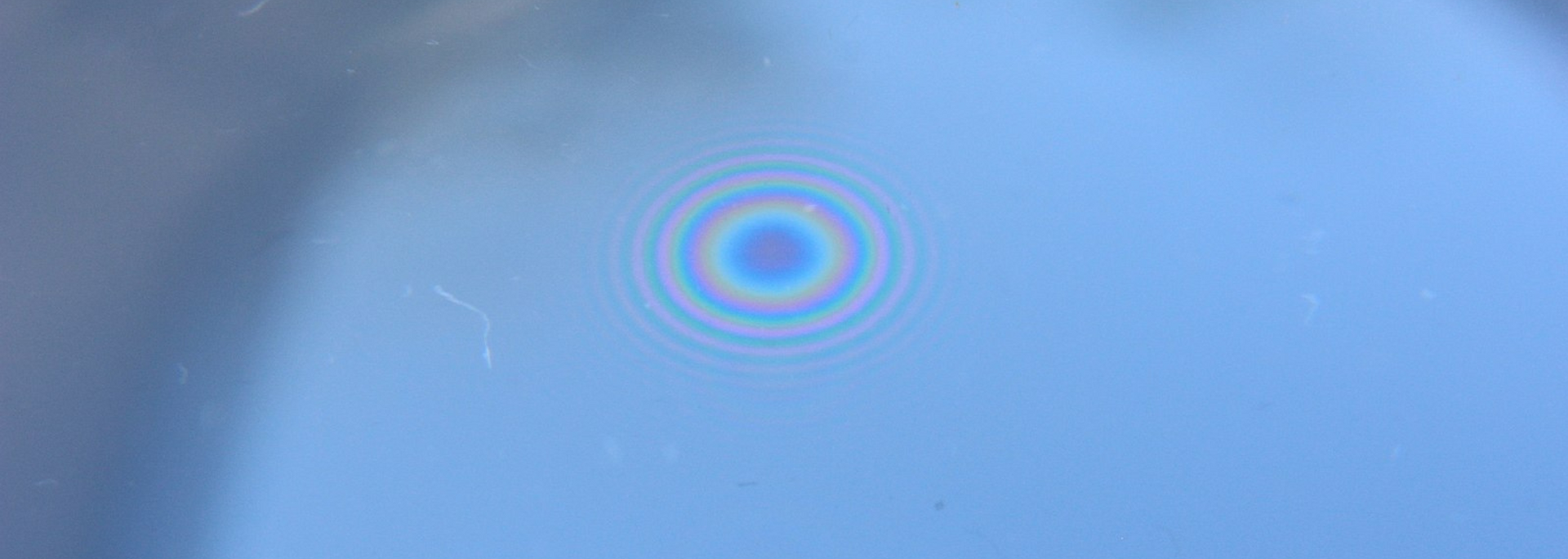

Newton's rings are commonly seen on insulated glass units (IGUs). They appear as concentric fringes at the points where two panes of glass touch within the IGU.

Unlike the distortions we've covered so far, Newton's rings are not a result of the glass manufacturing process. Instead, they're caused by two waves of light reflecting and interacting with one another.

There's not much you can do to change the properties of light. However, you can limit or eliminate the appearance of Newton's rings by installing your glass carefully and choosing a trusted IGU manufacturer.

For instance, the rings can crop up in situations where the spacer bar between two panes of glass is too narrow. Choose a wider spacer bar and – voila! – the problem goes away.

Even the height of the installation can make a difference. Newton's rings can sometimes appear when an IGU is sealed at a different altitude to where it's installed. The difference in air pressure can cause the panes to touch, which results in the visual distortion.

This is not a manufacturing defect per se, but it does highlight the importance of clear communication. Make sure to tell your IGU manufacturer or architectural glazier exactly where the glass will be installed. This is the best way to minimise or eliminate Newton's rings and similar distortions.

Brewster's Fringes

Like Newton's rings, Brewster's Fringes are caused by the interaction of light waves – not by any inherent property of the glass.

They're hard to see and usually only appear under very particular lighting conditions. However, if you do spot them, they'll be at the point where two panes of glass are installed in parallel (in an IGU, for instance).

Brewster's Fringes appear as wavy lines or irregular shapes. If in doubt, gently poke the glass. Brewster's Fringes will change their shape in response to this light pressure.

Like many types of visual distortion, Brewster's Fringes do not indicate a manufacturing defect. In fact, they only appear in situations where high-quality glass is used.

On the bright side, they're barely ever visible. You shouldn't have to replace your glazing if Brewster's Fringes are present.

Is glass distortion getting worse?

Yes and no.

The answer's "no" because glass fabricators, processors and installers are constantly finding new ways to minimise distortion. As we've seen, visual distortions can never be eliminated, but modern glass processing techniques come close.

But the answer is also "yes". Or, rather, "no, but distortions are becoming more visible".

This is because building projects are increasingly specifying low-emissivity (low-e) glass to combat glare, manage UV transmission and improve thermal efficiency.

Low-e glass is more reflective than regular glass. This increase in reflectivity makes visual distortions more noticeable.

So, keep that in mind before you write that strongly worded letter. If you're using low-e glass and notice visual distortion, it's probably not the glass's fault.

ToughGlaze is a trusted UK glass processor based in Bedford. Since 1993, we've supplied high-quality glass for architecture, construction, the glazing industry and many other sectors. Need BSI-certified glass for your next project? Get in touch today for a quick, competitive quote.