Haymarket Edinburgh

Mixed-use development case study

Weaving new ideas

Learn how an innovative approach to product development helped ToughGlaze put the finishing touches on Edinburgh's £350-million Haymarket complex.

How it started

A jewel in the heart of the Scottish capital.

Haymarket Edinburgh is a £350-million mixed-use development in a prized location close to major transport links. The project promises to create a "world-class setting for business, leisure and hospitality", attracting investment and footfall for an already-thriving commercial district.

Renowned architects Foster + Partners were brought on board to design Haymarket's four main buildings. Together, these comprise 380,000 square feet of office space, 40,000 square feet of retail space and a 362-bedroom hotel.

Before long, Foster was drawing up plans for an attractive, modern complex that would enhance and complement the area's distinctive architecture. The buildings would be "simple and calm" – and would be designed to maximise natural light.

This called for lots of glass. It was time to call ToughGlaze.

What happened next

A tough challenge for our technical team.

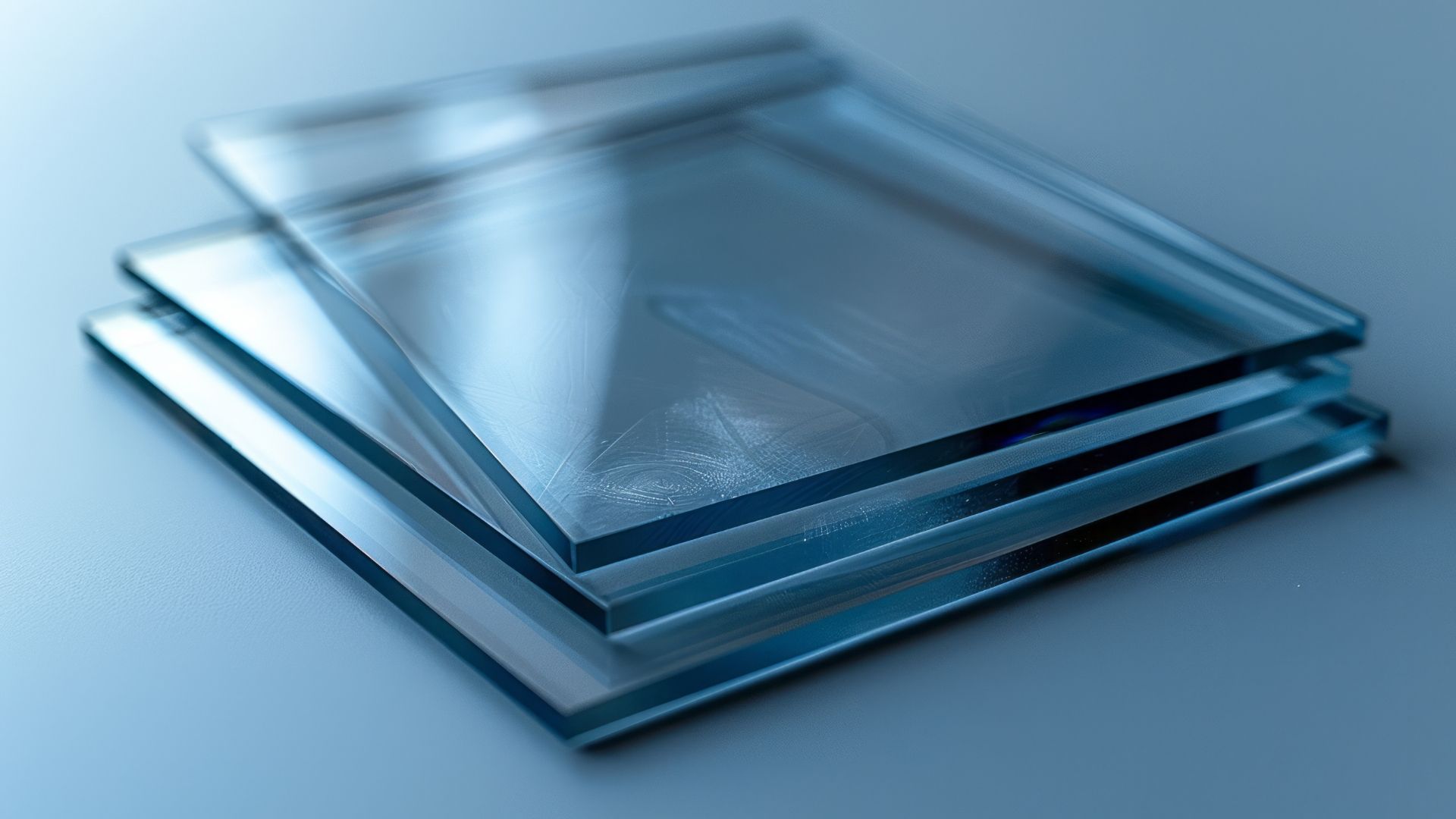

Foster + Partners asked ToughGlaze to design a bespoke mesh-laminated glass product for 1 Haymarket Square. This is one of three large office buildings that form the northern and eastern boundary of the development. The mesh laminate was to be installed as wall cladding within the building's double-height reception area and seven public-facing lift lobbies.

Our team knew it had a challenge on its hands. Foster had already specified a similar laminated glass for the building's exterior cladding – and this new product would have to be a perfect visual match. What's more, Foster wanted to incorporate a thick, expanded metal mesh that would be difficult to laminate using traditional techniques.

Difficult – but not impossible. Challenge accepted.

ToughGlaze delivers

Innovation wins the day.

Our technical got straight to work, developing a novel lamination technique that allowed for seamless material adhesion, even with thick or expanded mesh interlayers.

We'd leapt the first hurdle and nailed the spec. Foster + Partners would receive just what they asked for: a 10mm extruded metal mesh interlayer enclosed within two 4mm glass substrates.

Now we had to refine the design. So, working closely with the architects, we initiated a careful testing and sampling process to ensure perfect aesthetic and technical performance in situ. It was this attention to detail, along with the quality of the finished product, that ultimately saw ToughGlaze win the tender.

But our job wasn't over yet. We were also tasked with fabricating the 600+ wall panels at our state-of-the-art processing plant. In total, we produced more than 1,200m² of mesh laminate – all delivered on time and on spec.

The key facts

600+

Glass panels

1,200m²+

Total coverage

Bespoke

Mesh laminate

How we did it

Explore the ToughGlaze products that helped bring Glasgow School of Art back to life.

TG TL

Laminated glass

We supplied more than 1,200m² of high-quality, Kitemark-approved glass laminate.

TG MI

Mesh interlayers

Haymarket's architects specified a bespoke metal mesh interlayer – and our team delivered.

About ToughGlaze

For more than 30 years, ToughGlaze has championed quality and innovation in the UK glass industry.

Today, we operate from one of the nation's largest and best-equipped glass processing facilities. This means more choice, better value and fewer procurement challenges for customers like you.

When you work with ToughGlaze, you can source everything from toughened and laminated glass to innovative products like smart glass and mesh laminates. And thanks to our robust logistic function, you can expect to receive your order on time and in one piece – wherever you are.

We aim to be the only glass processor you ever need to work with. Get in touch today to learn how our experience can help you secure a competitive advantage.

Join Our Newsletter — No Spam, Just Expert Tips and Updates for Your Next Construction Project!

| ToughGlaze LTD