Glasgow School of Art

Public sector construction case study

From ruin to renaissance

Discover how ToughGlaze helped the Glasgow School of Art rise from the ashes with a brand-new structural glass facade.

How it started

Disaster strikes – twice.

On the evening of 15 June 2018, a fire tore through Charles Rennie Mackintosh's iconic building at the Glasgow School of Art (GSA).

The cause is still unknown – but the devastation was clear as day. The historic Mackintosh Building was gutted and several adjacent buildings were also caught in the blaze.

To make matters worse, this wasn't the first fire. Only four years prior, much of Mackintosh's celebrated library had been lost to another inferno – and the school was on the brink of completing a £20 million restoration project when the second blaze happened.

The GSA had to start from square one. The Mackintosh Building needed to be stabilised, cleared and faithfully restored – and parts of other school buildings would need to be torn down and replaced.

That included a modern rainscreen facade on the nearby Reid Building

What happened next

A tough solution to a tricky spec.

Replacing the Reid facade was no simple task. Its design was unique and complex, with a bespoke fixing system and demanding structural requirements.

However, this wasn't just a like-for-like replacement. While the new glass would have to match the look and feel of the old facade to a T, it would also need to outperform it.

But we love a challenge. And so, we got to work on a product that would meet and exceed the GSA's specification.

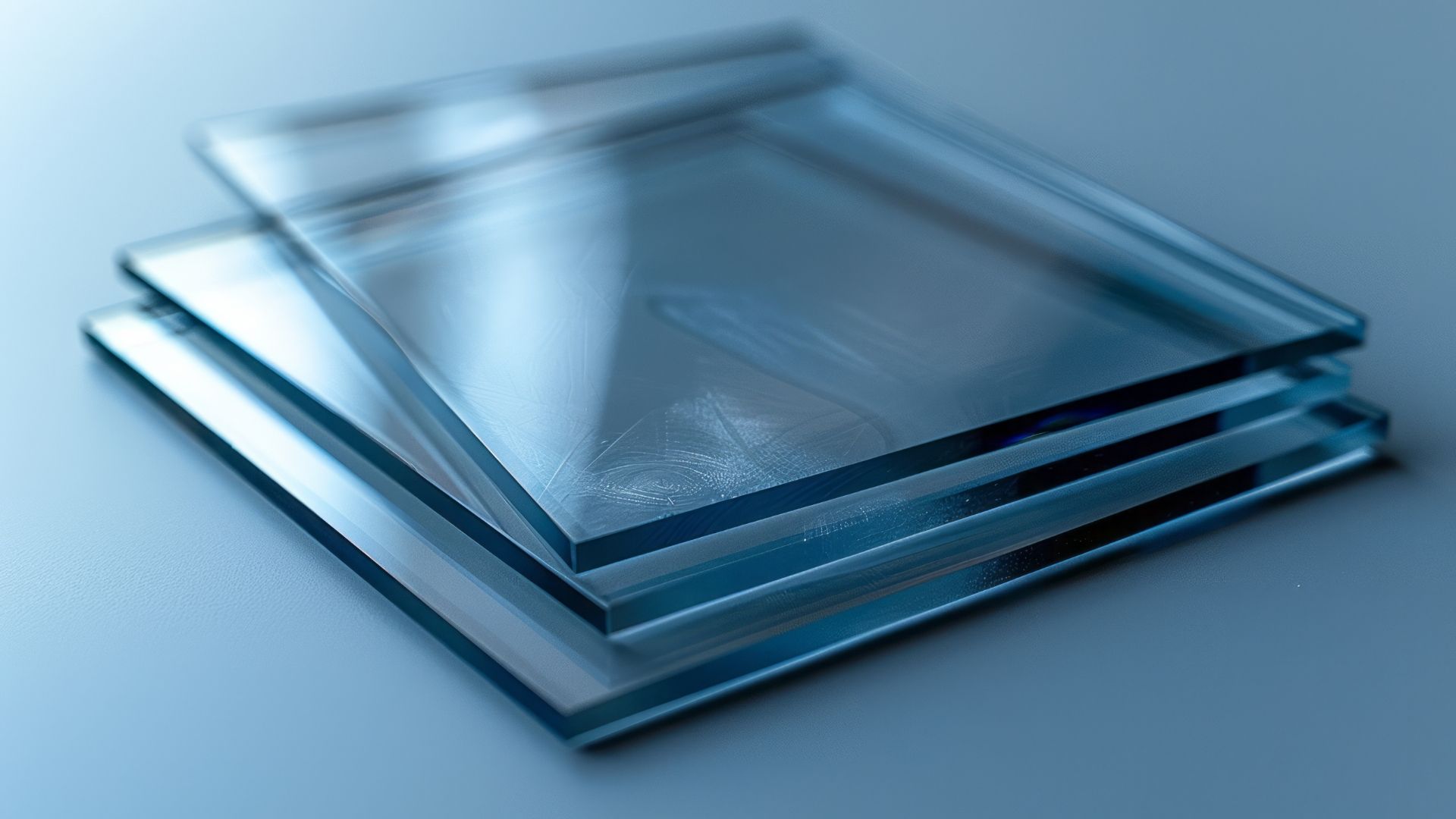

Our engineers developed a robust glass laminate that incorporated our unique water-resistant interlayer and invisible structural fixings that are laminated into the glass.

Competition was fierce – and the testing process was even tougher. Our laminate went through an intensive sampling and mock-up process, where full-size panels were independently tested to destruction.

The test results came back. Our bespoke solution had significantly outperformed two competing products. The contract was ours

ToughGlaze delivers

Our cutting-edge glass processing plant wins the day.

The GSA needed its new glass – and it needed lots of it. More than 1,000m² of the stuff, in fact.

And these weren't your common-or-garden glass laminate panels. They were complex, bespoke products that required careful manufacturing in stages.

The glass needed to be cut to size and laminated with several specialist interlayers – along with the proprietary structural fixings we'd developed in-house.

For many glass suppliers, this would be a problem. But ToughGlaze operates from one of the UK's most advanced glass processing plants. This allows us to manufacture up to 300m² of laminated glass per day – and handle all the processing steps under one roof.

For our partners, this means minimal overheads and operational headaches. The GSA project was complex – but thanks to our cutting-edge facilities and well-oiled manufacturing process, we were able to deliver all 315 glass panels in good time.

The key facts

315

Glass panels

1,030m²

Total coverage

Bespoke

Structural glass system

How we did it

Explore the ToughGlaze products that helped bring Glasgow School of Art back to life.

TG TL

Laminated glass

We supplied more than 1,000m² of high-quality, Kitemark-approved glass laminate.

TG SGF

Structural glass fixings

The school specified a unique invisible fixing system – and we delivered.

TG CI

Coloured interlayers

The finishing touch? A translucent interlayer from our palette of more than 3,000 colours.

About ToughGlaze

Top of our glass since 1993.

ToughGlaze has been a leader in the UK commercial glass industry since 1993.

It's all thanks to our no-nonsense, quality-led approach. When you work with us, you can expect high-performance glass products that meet the needs of the modern construction and architectural industries. And you can expect them to arrive on spec and on time – every time.

Need glass? You need the experts. Get in touch and take advantage of our industry-leading knowledge and unmatched manufacturing capabilities.

Join Our Newsletter — No Spam, Just Expert Tips and Updates for Your Next Construction Project!

| ToughGlaze LTD