What are the three main types of fire-rated or fire-resistant glass? Learn all about it in our expert guide.

Glass is a critical material in the construction industry. But until the late 19th century, it had a problem. It was easy to break and, in the event of a fire, it wouldn't last long.

Fast forward to the 21st century and the market is saturated with fire-rated products that can withstand smoke and flames.

However, not all fire-rated glass products are the same. Some, to put it bluntly, are better than others.

This is because some fire-rated glass has a level of impact resistance similar to that of safety glass. At the time of writing, this is far from being the industry standard. It's also because some fire-rated glass can withstand fire for different lengths of time – from a minimum of 30 minutes up to two hours.

Too often, we see customers buying substandard fire-rated glass. This isn't to say it isn't safe – just that it could be safer.

But before we tell you more about our own fire-rated glass product, let's explore the different types on the market.

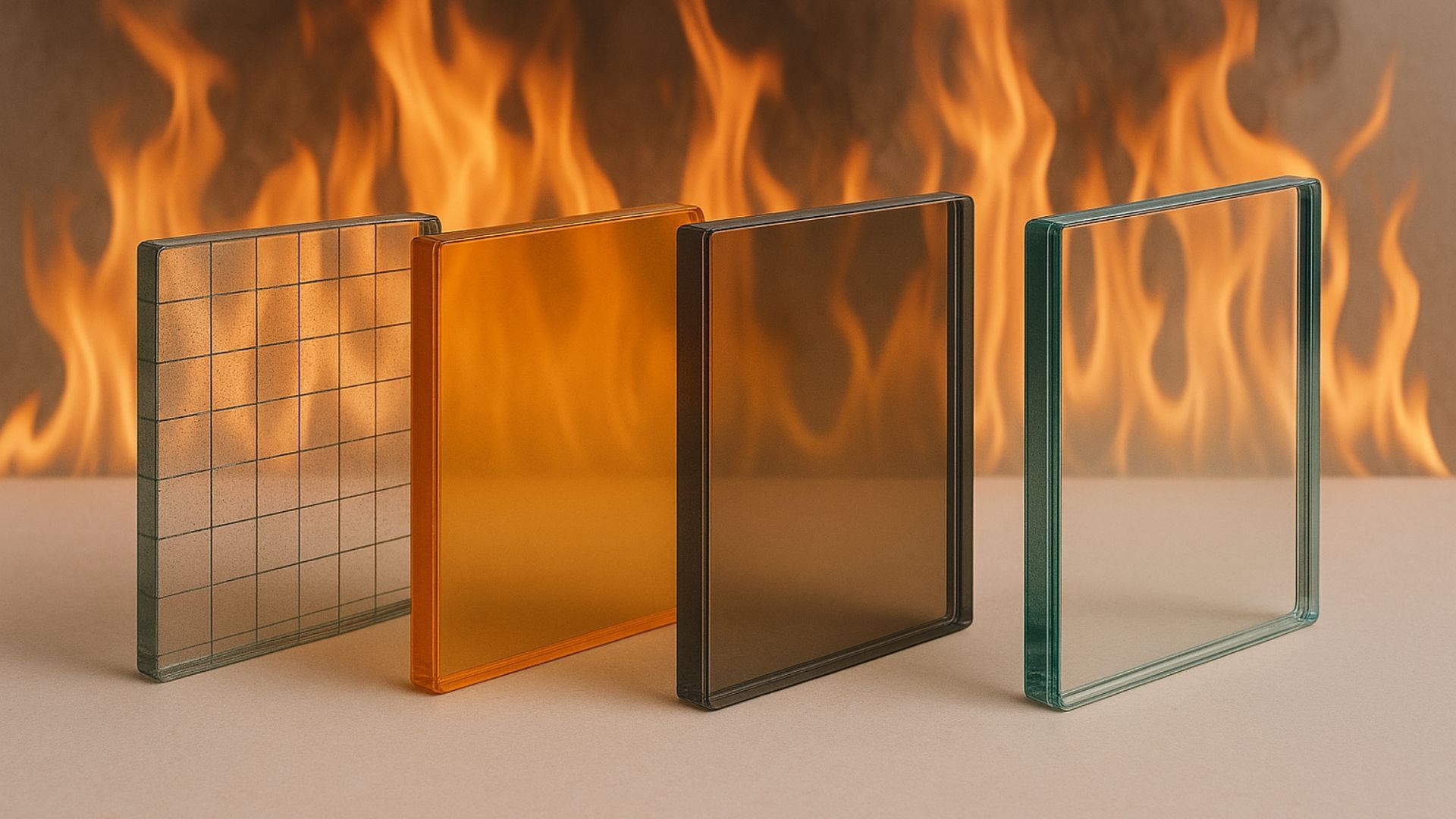

The three main types of fire-rated glass

Glass is a bit like medicine: it can be categorised according to its type or according to brand names. In this article, we're focusing on the main types rather than particular brands.

The three main types are E, EI and EW. Each has a different level of fire resistance and, for this reason, suits some applications better than others.

E-type fire-rated glass provides integrity but not insulation. It tends to be a single pane of toughened glass or cuttable wired and laminated glass. E-type glass can stop fire from getting through but doesn't stop heat transfer. It's safe, for sure – but it offers only the bare minimum in terms of fire resistance.

EI-type fire-rated glass, by contrast, provides both integrity and heat insulation. It's made out of two or more layers of glass enclosing a fire-resistant interlayer. This can be an intumescent foam or (as in the case of our fire-rated glass) a type of gel.

When fire breaks out, the interlayer in a piece of EI-type fire-rated glass expands, creating a barrier against the transfer of heat. This gives people more time to evacuate and the fire brigade more time to arrive.

Finally, there's EW-type fire-rated glass, which provides protection against fire and reduces heat transfer through the glass. It's specifically designed to keep radiant heat below 15kW/m2. EW glass can be toughened, gel-filled or laminated.

All three types of fire-rated glass come with a number. These numbers refer to the length of time the glass can withstand fire.

E30, for instance, offers a base level of protection for 30 minutes. Our flagship fire-rated product,

TG FR, is EI, offering integrity and insulation, and goes up to a whopping 120 minutes.

All three types of fire-rated glass play a pivotal role in keeping people safe in large buildings, be they industrial, commercial or residential premises.

Fire-rated glass can be used in doors, windows, screens and walls. They serve to provide protection against fire without blocking out the light or spoiling the view.

The rules surrounding fire-rated glass in the UK are covered in Approved Document B of the building regulations. E30 is the minimum fire rating. EI30 is required if a project is to have no upper limit on the amount of glass used.

When consulting building regulations, make sure you're looking at the most recently updated versions. This will help you avoid costly replacements down the line.

Different types of interlayers

In the not-so-good old days, fire-rated glass was made from a combination of glass and wire. But this had one major drawback. More often than not it failed to meet industry standards for impact resistance. In the USA, it was phased out altogether in 2006.

This led to the creation of types of fire-rated glass that could withstand heavy impacts as well as raging fires. Interlayers – layers of material sandwiched between two panes of glass – played a crucial role.

Interlayers can be made of resin or intumescent foam. An intumescent foam interlayer turns opaque and swells when exposed to fire. This swollen interlayer creates a barrier against the fire.

A less common type of interlayer is gel-based. This serves the same function as an intumescent interlayer but can boast impressive levels of fire resistance. This is the case with our

two-hour fire-rated glass, TG FR.

Introducing TG FR

At ToughGlaze, we're always looking for ways to improve our range and make sure we're at the cutting edge of glass processing. That's why we're now offering

TG FR – a type of fire-rated glass that combines the best in safety glass with the best in fire resistance.

TG FR is a toughened laminated glass product. This means it can withstand heavy impacts as well as fire.

But TG FR is special for another reason. It makes use of innovative gel technology to create a glass product that can withstand fire for up to two hours.

It works a bit like this. Between the two panes of toughened laminated glass is a gel interlayer. When exposed to fire, the inner-facing layer breaks off and shatters into tiny, harmless pieces. The gel turns opaque, staying intact and providing an insulating barrier for up to two hours.

And unlike some other fire-rated products on the market, it looks the part. In fact, you'd be hard-pressed to tell the difference between TG FR and any other toughened or laminated product in our range.

Whether you're installing fire-rated glass in a domestic, commercial or public setting, TG FR does the job – and then some. Interested? Don't hesitate to

get in touch with our experts for a quick, competitive quote.

Join Our Newsletter — No Spam, Just Expert Tips and Updates for Your Next Construction Project!

| ToughGlaze LTD