Toughened glass vs chemically strengthened glass

Share this blog:

Toughened glass, chemically strengthened glass, laminated glass… What's the difference? Read all about it.

When most people talk about glass, they talk about it as though it's just one thing. You know – glass! Everybody knows what it is and what it's used for, right?

In fact, glass is one of the most versatile and varied materials out there. The type of glass used to make your kitchenware, for instance, isn't the same as the type used for glass skyscrapers. Different applications and contexts require different varieties of glass.

You see this clearly (no pun intended) when looking at glass that needs to withstand pressure, heat or extreme weather. It goes without saying that the glass used to make a champagne flute isn't going to cut it. No – you need specialised glass that's fit for purpose.

There are different types of glass that are manufactured to be especially robust. In this article, we're going to look at two of them: tempered (or toughened) glass and chemically strengthened glass.

Both of these types of glass are processed in such a way that their outer surfaces are made more robust – and in both cases, the outer surface is compressed and the inside or "core" has a compensating tension. Nevertheless, they have different chemical structures and different applications.

What is chemically strengthened glass?

If you're reading this article on your smartphone, chances are that you're looking at a chemically strengthened glass screen. Chemically strengthened glass can be processed thinly, making it ideal for smartphone screens, photocopiers and some pharmaceutical devices.

To the layperson, the manufacturing process sounds like something out of sci-fi. A sheet of annealed glass gets plunged into a bath filled with molten potassium nitrate. This causes something called an "ion exchange".

Ions, you may remember from school, are atoms or molecules with an electrical charge. The potassium ions in the bath are larger than the sodium ions in the glass. The potassium ions squeeze into gaps in the glass, plugging it up and making it stronger.

As with toughened glass, the surface of the glass is compressed and the core is in a state of tension. But unlike toughened glass – or rather, lower-quality toughened glass – the resulting pane doesn't suffer from warping or other optical distortion.

Take a look at your smartphone screen. It may be chipped or smudged through use, but the glass itself is crystal clear and sturdy.

Once manufactured, it's possible to cut chemically strengthened glass, but it tends to weaken the area within 20mm of the cut. A similar loss of strength occurs when the surface gets a deep scratch.

How is chemically strengthened glass different from toughened glass?

Toughened or tempered glass is different from chemically strengthened glass both in its manufacturing process and in its applications.

First off, the glass that's being processed has to be thicker for toughening than for chemical strengthening. This is because of the internal stress that's put on the glass during the toughening process. Too thin and the glass is liable to shatter inside the furnace.

Secondly, toughened glass is a type of safety glass. When it breaks, it shatters into small particles – not jagged shards that can cause injuries.

Chemically strengthened glass, by contrast, breaks into long jagged shards, much like float glass. To be part of a safety glass, it has to be laminated.

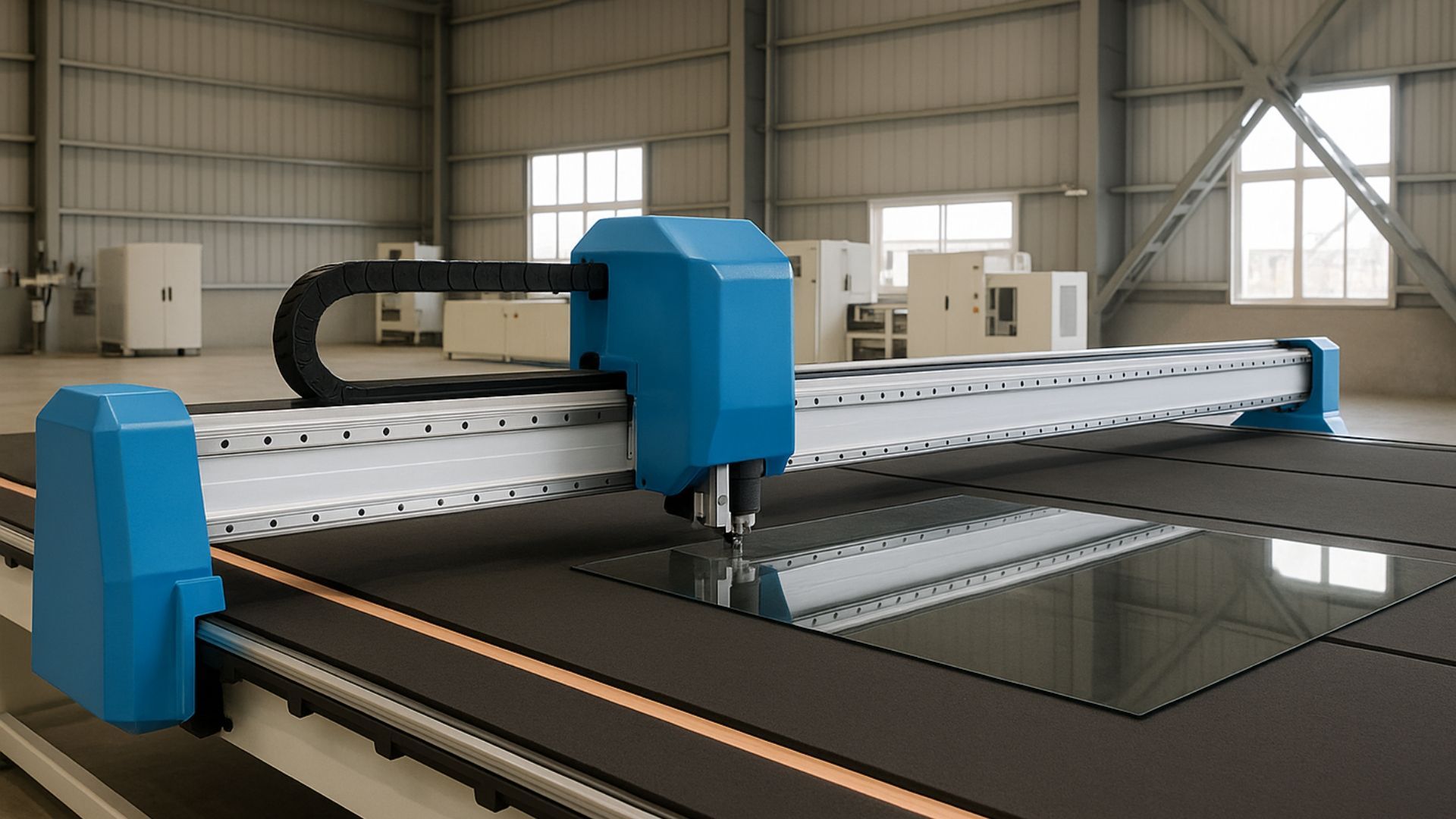

Thirdly and finally, toughened glass can't be cut or drilled without shattering. This means the glass has to be cut to the right size

before going into the furnace. By contrast, chemically strengthened glass can be cut after processing.

Taken together, these attributes mean that toughened glass is used in different contexts from chemically strengthened glass. Toughened glass is often found in industrial environments or settings where extra security is required. You also find it in windscreens and shower doors.

Whereas chemically strengthened glass is processed in a chemical bath, toughened glass is processed in a furnace. There, it's subjected to intense heat. Once out of the oven, it's rapidly cooled or "quenched" with blasts of cool air.

This dramatic shift in temperature causes the surface and edges of the glass to compress, resulting in a super-strong outer layer and a glass core with compensating tension.

What about laminated glass?

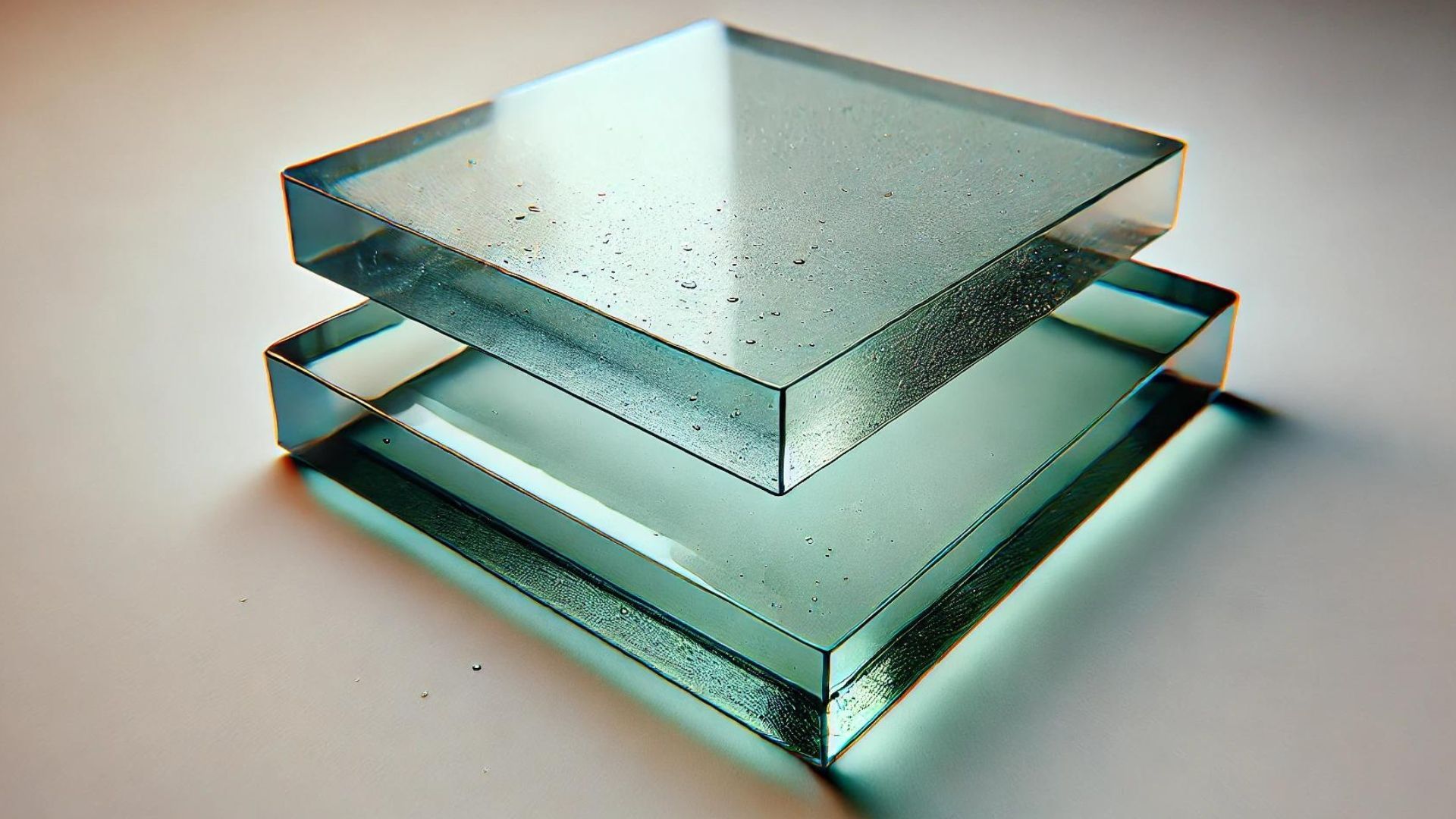

Laminated glass is a third type of glass that's built to withstand extreme heat, pressure and environmental conditions. To give you a sense of its robustness, this is the type of glass that's used for glazing in parts of the world vulnerable to hurricanes, as well as for glass walkways, staircases and other architectural features designed to be walked on.

It's a kind of glass sandwich, with at least two panes of glass and a plastic interlayer in the middle. This interlayer bonds the outer sheets together and ensures they don't break into dangerous pieces.

The key difference between toughened glass and laminated glass is the way it breaks. If you smash a toughened glass shower door, it will break into lots of little pieces. But if you try to smash a laminated windscreen, it won't shatter at all. Instead, you'll see a pattern not unlike a spider's web spread across the screen.

As with toughened and chemically strengthened glass, laminated glass gets its properties from the manufacturing process. The sheets are taped around a plastic interlayer, sealed inside a hot silicone bag and put in the oven.

The intense heat of the furnace bonds the layers together. Exactly how long this takes depends on the thickness of the glass in question, but it tends to be between three and four hours.

About us

Here at ToughGlaze, we're

safety glass specialists. Our range includes everything from standard toughened panes to laminated glass. From switchable smart glass to coloured glass. And from sandblasted, etched and frosted glass to mirror glass.

So if you're in the market for some high-quality glass,

get in touch. We'd love to fix you up with the right materials for the job.