The role of automation in the glass industry

Share this blog:

Automation increasingly plays a key role in glass manufacturing. Discover how in our explainer article.

The basics of glass manufacturing are simple. Take some sand and heat it until it's very, very hot. Eventually, you'll get glass.

But despite this simple recipe, glass has been manufactured in a variety of ways across the centuries. The sheer range of methods is demonstrated by the fact that in 2024, you can still find people blowing glass, while at the same time, factories use artificial intelligence to optimise glass-cutting.

Overall, however, the trend across the centuries has been towards greater mechanisation – from cutting wheels and edge grinders you operate manually to machines that do the job more safely.

In turn, mechanisation is being supplemented and in some cases supplanted by automation. As in other industries, more and more jobs are being given to robots. Advocates argue that it unlocks efficiencies otherwise denied them.

In this article, we explore the fascinating world of automation in the glass industry.

What is automation?

Automation is when a piece of technology executes a task without human intervention.

In the popular imagination, automation is overwhelmingly associated with robotics. But it can be as simple as the humble toaster.

Before the Age of the Toaster, you had to watch your bread go brown and decide when it was ready. Not the end of the world, sure – but something you can do without when you're bleary-eyed and ready for breakfast.

A toaster automates this process. You, the human, put the bread in the slot and set the time. The toaster pops it out when it's ready – no human intervention required.

In the kitchen and around the house, automation is labour-saving. In the context of manufacturing, it saves costs as well as labour. In many cases, manufacturers are happy to employ fewer staff and let machines carry out routine tasks.

There's no getting around the fact that automation can have a negative effect on the job market. On the plus side, machines are less prone to error when executing mechanical tasks. A human can put a piece of bread under the grill and get distracted. A toaster will give you the toast you like time and time again.

A brief history of automation in the glass industry

For a long time, glass manufacturing was manual – and not just glass manufacturing. In fact, the word "manufacture" comes from the Latin

manu factum: "made by hand".

It wasn't until the mid-20th century that manufacturers started to use conveyor belts, cranes and other bits of mechanical equipment. This allowed them to produce glass on a larger scale than ever before.

The 1970s saw the advent of computerisation. Computers were used to regular temperatures and monitor production, as well as provide software to keep track of inventory, payroll and other admin.

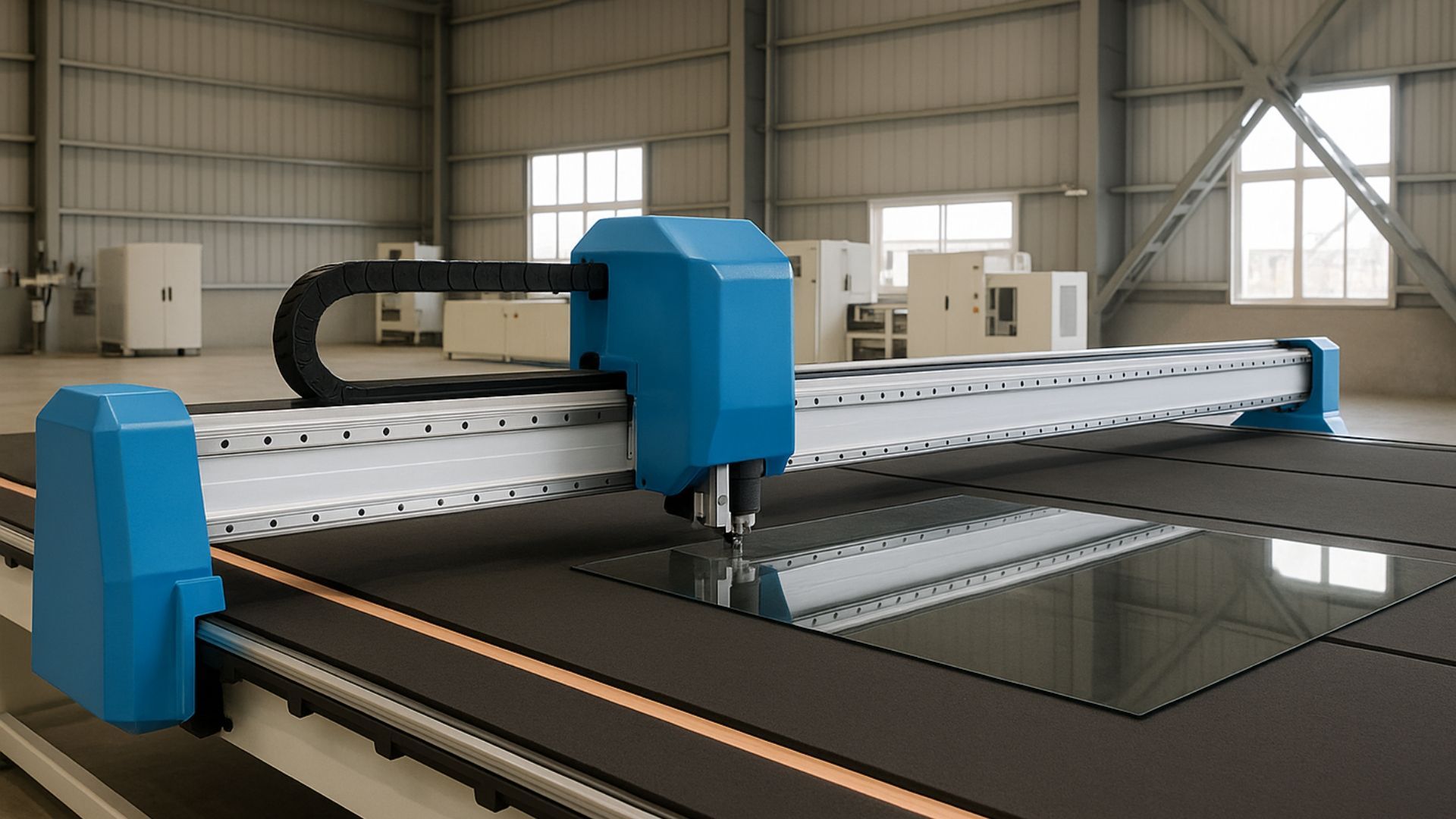

Computerisation also introduced CNC machines and auto-lathes – machines that execute designs fed to them by a computer. As with your toaster, the margin of error is much smaller than if a human were to cut the glass by hand.

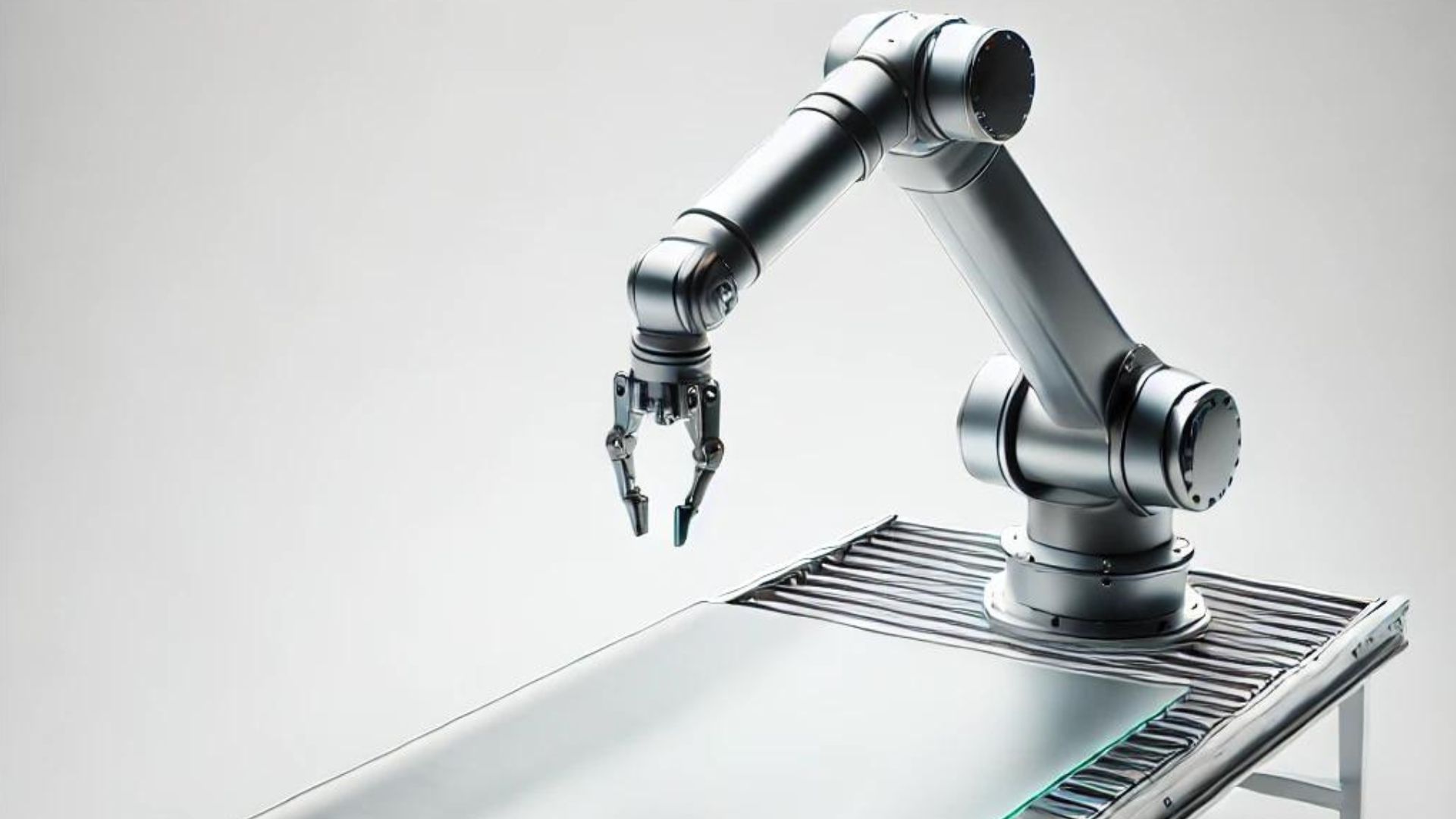

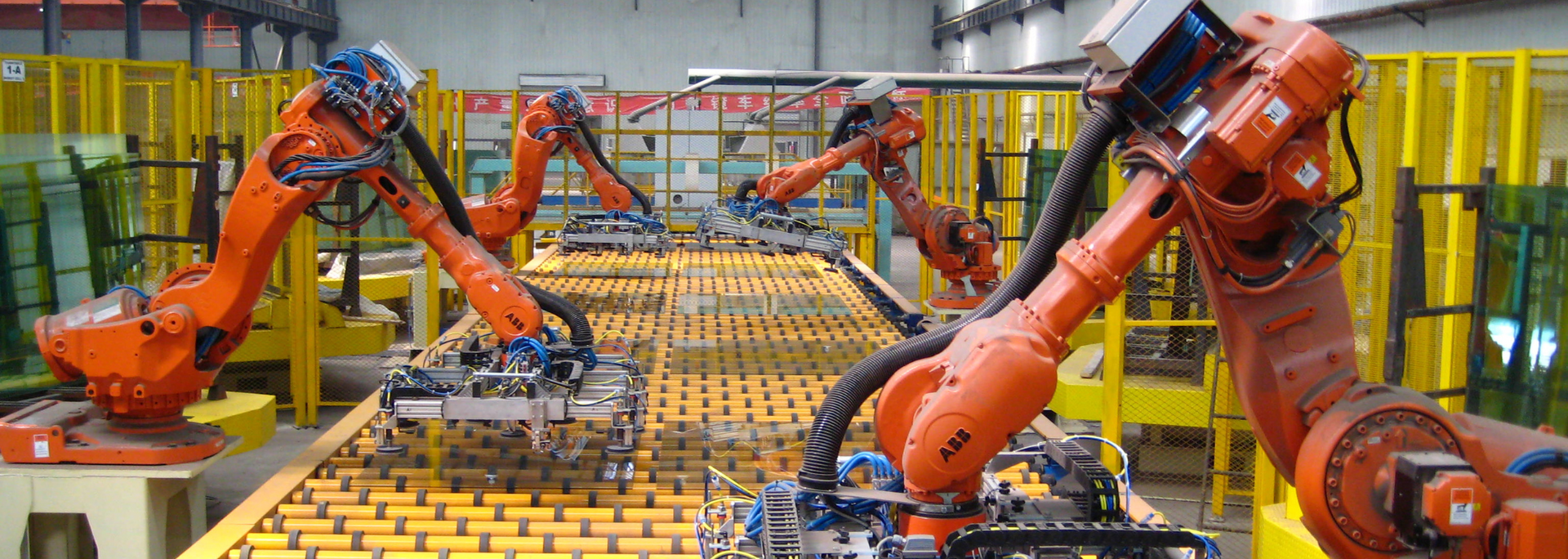

Robotics came onto the scene in the 1980s. Robots were used to handle and manoeuvre glass pieces. This type of automation is used primarily for tasks that could put humans at risk – placing glass in the furnace, for example.

Then from the 1990s onwards, the glass industry began to embrace artificial intelligence and machine learning. This is where computers analyse huge data sets to draw conclusions that inform everything from design to manufacturing to delivery.

What are the benefits of automation to glass manufacturers?

From the point of view of a glass manufacturer, automation has several benefits.

The first relates to productivity. Machines can perform some tasks more quickly and efficiently than humans – and unlike humans, they don't need breaks. This allows manufacturers to meet demand more easily.

Robots also make fewer mistakes than humans. CNC machines, for instance, can cut glass with greater precision than a human could.

Manufacturers that employ automation on the production line spend less on labour. They also spend less on waste by making the cutting, firing and treating processes more efficient.

Glass manufacturing can be hazardous, exposing humans to burns, cuts and other injuries. By automating routine tasks, humans are kept out of harm's way. Robots can also monitor factors such as furnace temperature to reduce the risk of accidents.

How is AI used in the glass industry?

AI is hot property at the moment, largely thanks to ChatGTP and image generators going mainstream. Many applications of AI in manufacturing are less headline-grabbing but no less impressive. Here are four that are increasingly used in the glass industry.

1. Glass-cutting optimisation

When you cut glass by hand, or even by machine, you can create waste material. This is bad for the environment as well as the manufacturer's bottom line. AI can find the optimal lines and measurements to cut, resulting in a more exact finished product.

2. Product development

Product development drives the industry, but it's often expensive to do. It can also be risky if, like glass, the product involves chemicals. Ideas don't generate themselves – not unless you get AI involved.

AI lets you spin up and dispose of ideas quickly and easily, meaning that manufacturers can workshop new products at a low cost.

3. Supply chain optimisation

Like all industries, the glass industry depends on a complex network of suppliers and logistics. Inefficiencies in sourcing materials lead to delays, and delays lead to excess costs.

AI can address this problem by forecasting demand, identifying optimal delivery routes, predicting inventory shortages, and more. It does this by analysing huge data sets and spitting out actionable insights.

4. Predictive maintenance

AI can evaluate data from machine sensors and logs to predict when maintenance is needed. This allows manufacturers to schedule repairs for off-peak times, reducing operational downtime.

ToughGlaze is one of the UK's most trusted

suppliers of toughened glass, laminated glass and decorative glass products.

Learn more about our 30+ year history or

get in touch for a fast, fair quote.