Parallelism in glass fabrication: what is it, exactly?

Share this blog:

What is parallelism, and how does it affect the quality of glass? Learn all about it in 5 straight minutes.

How do you know if a pane of glass is good quality?

You could answer this question in different ways. You could look for assurances that it's durable, customisable, energy-efficient or transparent. You could look at the price tag. You could look for the fabricator's accreditations, online reviews and reputation.

All these factors are important. But as with many consumer goods, the quality of a sheet of glass is the result of many minute calculations and methods. These are details that may seem trivial to the untrained eye. Nevertheless, they're an important marker of quality.

Parallelism in glass fabrication is one such detail. It's a matter of minuscule measurements that contribute to the overall quality of the finished glass product.

This doesn't just matter to fabricators and quality assurance officers. It also matters to customers who want high-quality glass, no matter the application.

So, what is parallelism, and why does it matter? Let's take a closer look.

What is parallelism in glass fabrication?

Parallelism in glass fabrication is a matter of tiny measurements. It refers to the degree to which the front and back planes of a piece of glass run parallel to each other.

The more parallel those planes are, the better the product. This is true in domestic and commercial settings and covers purely functional installations, decorative displays and everything in between.

But as with many aspects of glass fabrication, perfection is not possible. Despite the scientific nature of the industry, there are simply too many variables to ensure perfect parallelism. Nevertheless, a good glass fabricator will make sure its glass products are as parallel as possible.

Side-bar: just in case you're wondering, parallelism in glass fabrication has nothing in common with parallelism in grammar or in computing.

Why is parallelism in glass fabrication important?

Parallelism in glass fabrication isn't something you can observe straight away, like warping, bowing or other types of glass distortion. It's something that only becomes apparent when installed.

Essentially, parallelism minimises distortion – distortion that can degrade the quality of light or images displayed on or transmitted through the glass.

In a window, for instance, poor parallelism will lead to poor optimal performance. The same goes for polarisers – those optical filters applied to camera lenses, tablets and other devices.

Parallelism alone won't make or break a successful fabrication job. But it's one hallmark of quality that a reputable processor will take into account and minimise wherever possible.

Can perfect parallelism be achieved?

The American football coach Vince Lombardi is quoted as saying, "Perfection is not attainable, but if we chase perfection, we can catch excellence." This applies to glass fabrication in general and parallelism in particular.

Perfect parallelism is the stuff of fairytales. However, fabricators set limits for accuracy known as "tolerances".

We've explored

the issue of glass tolerances before. In the case of parallelism, the tolerances are tiny but important.

They can be measured in three ways. First, there's transmitted wavefront error (TWE). This measures the deviation in degrees of a wavefront when a beam is transmitted through glass.

Secondly, there's total thickness variation (TTV). This measures the difference between the minimum and maximum thickness of the glass. Thickness variations can be brought down to less than one micrometre (0.001 millimetres).

Finally, parallelism can be measured in arcseconds. An arcsecond is one-sixtieth of an arcminute, which in turn is one-sixtieth of a degree. Fabricators will typically set tolerance levels somewhere between a few arcseconds and five arcminutes.

As you can see, it gets very technical very quickly. But the key takeaway is clear. These are tiny measurements that contribute to the overall quality of the glass.

And because they're so tiny, you need to work with a glass fabricator or processor that knows its micrometres from its millimetres and has the equipment to minimise parallelism as much as possible. The same goes for other kinds of glass distortion.

What other kinds of glass distortion are there?

Like parallelism, glass distortion can't be eradicated. However, it can be minimised by good manufacturing practices at state-of-the-art facilities.

Other common kinds of glass distortion include:

- Roller wave distortion. This causes images reflected in the glass to appear rippled. We've covered it in more detail here.

- Bowing and warping. This is when the pane isn't perfectly flat.

- Anisotropy or iridescence. This is a type of distortion most commonly seen in heat-treated glass. Stress patterns in the glass's cross-section become visible, leading to parts of the glass appearing darker than others.

- Optical distortion. This is a more general term that refers to imperfections in the way sunlight or artificial light passes through the glass.

- Pillowing. This type of glass distortion is found in insulated glass units (IGUs). It results in the cavity between the glass panes expanding and contracting as the temperature changes.

We'll say it again: distortion in glass fabrication can't be eradicated. To some degree, it's an inevitable byproduct of the manufacturing process. But if you want distortion to be reduced to its bare minimum, you need to work with a reputable, experienced glass processor.

How we can help

At ToughGlaze, we prioritise quality in our glass products. This goes for our whole range, from plain

toughened and

laminated glass to customised

decorative glass products.

Part of this involves minimising distortion in our glass products wherever possible. We strive for optimal parallelism and minimal optical distortion. We also provide heat soak testing on request to minimise the chances of nickel sulfide inclusions in your glass.

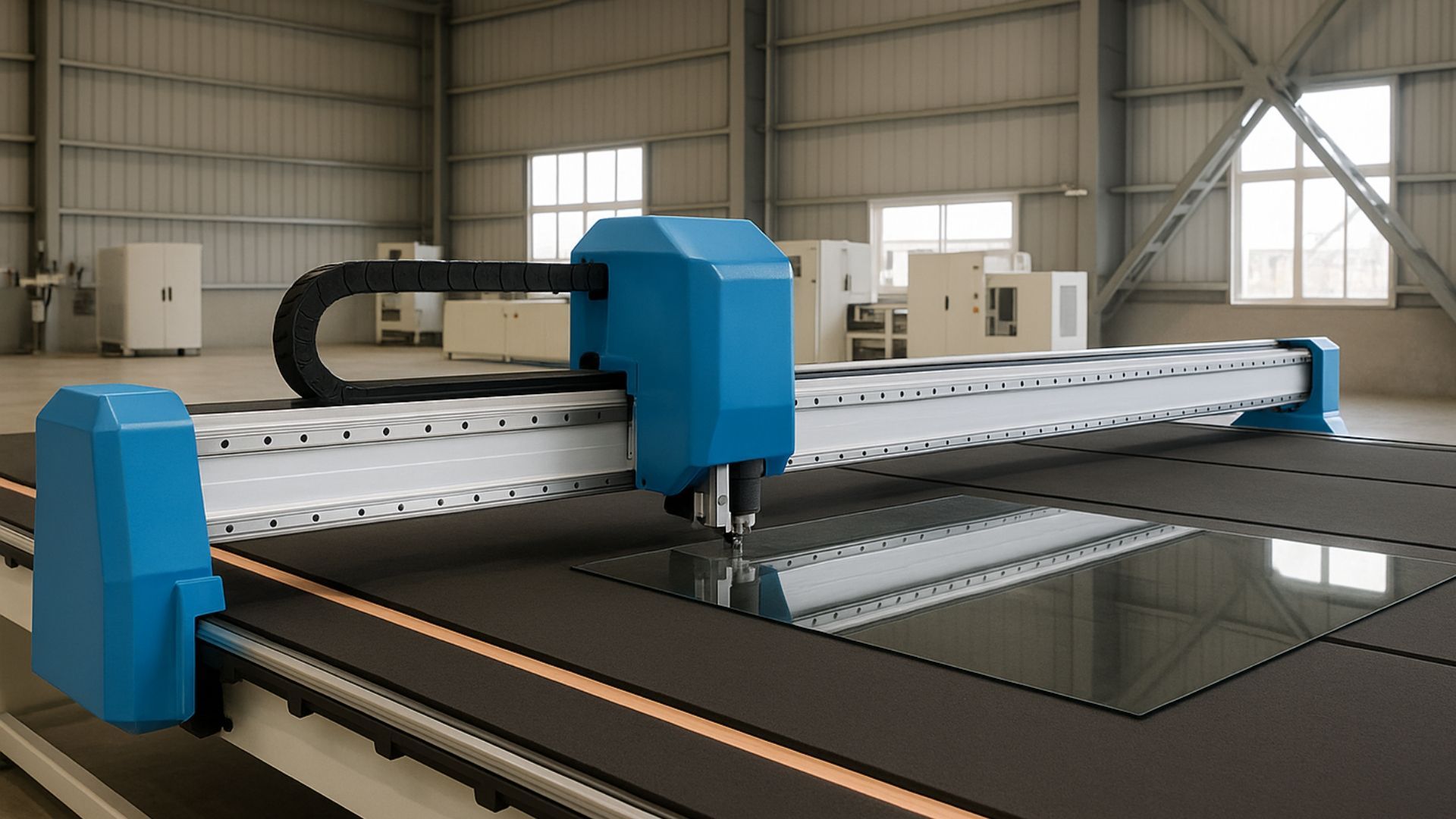

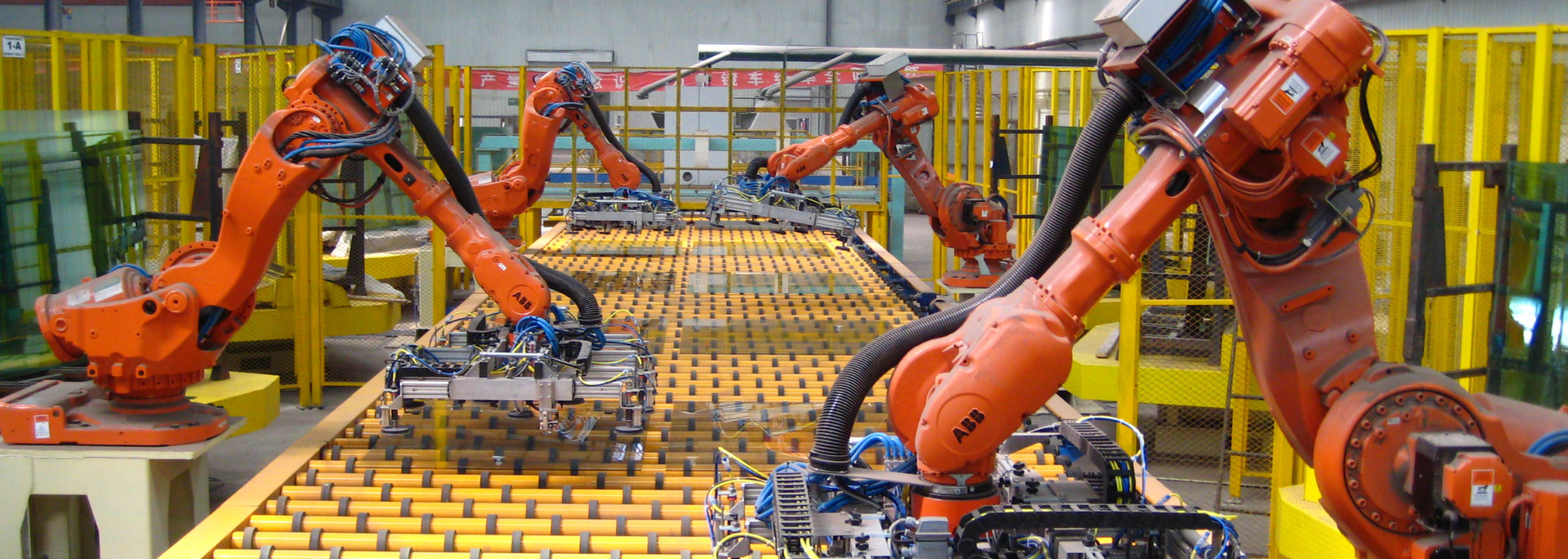

Everything is done here at our state-of-the-art facilities. We cut, fire, treat and deliver products to clients all over the world.

So, if you're looking for high-quality glass in all its forms,

get in touch with ToughGlaze for a quick, competitive quote.

We look forward to hearing from you.