Our glass suppliers: what you need to know

Share this blog:

A glass processor is only as good as its glass. Learn the key facts about our main glass suppliers.

In the British political comedy series The Thick of It, spin doctor Malcolm Tucker says: "You give me Hugh Abbot, I give you bangers and mash. But if you give me Jerry from the Home Office, well, then I can raise it to risotto and scallops."

What's true of politics and

Ready, Steady, Cook is true of glass, too. A glass processor can do many things for you. But they'll only ever be as good as the materials they use.

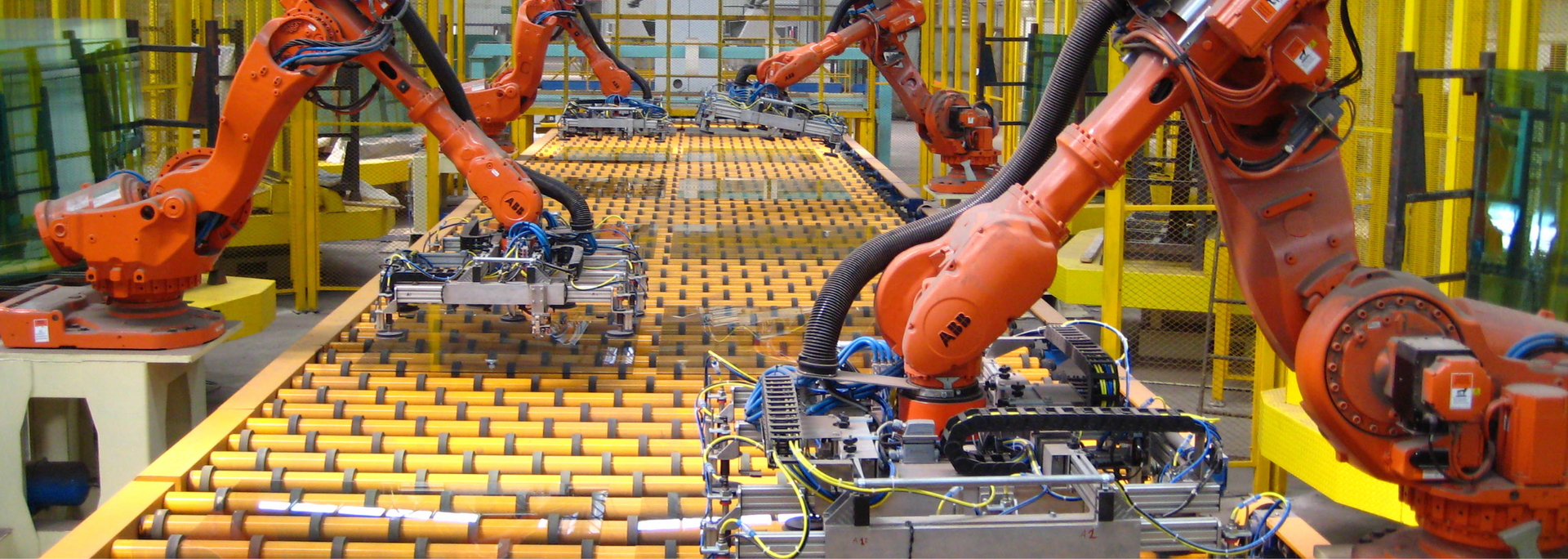

They can

toughen or

laminate it. They can decorate it with

coloured interlayers. They can frost it, tint it or make it

"smart". They can

heat soak test it. They can make it extra tough – tough enough to withstand a

bullet or a

bomb blast.

But that's what's on the menu – not what comes out of the kitchen. To increase your chances of customer satisfaction, you need to be sure that your processor gets its glass from reputable sources. It's at least as important as word of mouth, online reviews or industry accreditations.

At ToughGlaze, we're sticklers for quality. Only a small selection of glass suppliers will cut it. It's one of the markers of quality that makes us one of Britain's most trusted glass processors. Whichever product you order, you can be sure it's made from industry-leading raw materials.

In this article, we're going to tell you everything you need to know about three of the best: Guardian Glass UK, Pilkington, and Saint-Gobain Building Glass.

Guardian Glass UK

Guardian Glass UK is a branch of Guardian Industries: a manufacturer of glass, automotive and building products that serves the globe from its base in Michigan, USA.

It has supplied glass processors with high-quality float glass for decades. But it started life in the early 1930s as a manufacturer of windscreens. When Pilkington introduced float glass in the 1950s, it quickly adopted this new technology.

Guardian opened its first production line in Carleton, Michigan. Today, it has 28 float glass lines and 13 glass fabrication plants worldwide.

These include Guardian Glass UK, based in the Capitol Park industrial complex in Goole, East Yorkshire. Goole is a port town on the River Ouse. The arrival of Guardian in the area created hundreds of new jobs.

At one point, Guardian and Pilkington were at loggerheads, fighting over the use of float glass. This was because Pilkington had a monopoly on the float process via its licensing procedures.

Initially, Guardian tried to challenge this monopoly. In the end, it helped Pilkington become less vulnerable to antitrust laws in the States. In other words, it helped Pilkington grow to serve its own interests.

Today, Guardian is one of the leading providers of float glass in the UK – and we're proud to count it among our key suppliers.

Pilkington

These days, Pilkington is a subsidiary of the Japanese company NSG (Nippon Sheet Glass). But it started life in 1826 as St Helens Crown Glass Company in St Helens, Lancashire.

Originally, it belonged to the Pilkington and Greenall families – but after the partnership ended in 1845, the company rebranded as Pilkington Brothers. Despite this severed alliance, Pilkington was just getting started.

At the turn of the 20th century, Pilkington was Britain's only plate glass manufacturer – and the number one producer of sheet glass. Its grip on the glass market only grew when it acquired its main competitor in 1951.

By that point, Pilkington was practically a British institution, thanks to its significant contributions to the war effort.

Yet it was the 1950s that saw Pilkington leave its greatest mark on the industry. In that decade, it invented float glass.

Before float glass, plate glass had to be ground and polished. It was a time-consuming and expensive process – and the results weren't as clear as the glass we're used to today.

Float glass streamlined the process by floating molten glass over a bath of molten tin. It cut lead times and produced glass that was clearer and more robust than ever.

Not content with revolutionising the manufacture of glass, Pilkington went on to become a major global supplier of both toughened and laminated glass.

Saint-Gobain Building Glass

Of our three main suppliers, Saint-Gobain is the oldest – but that doesn't mean it's stuck in the past.

When Saint-Gobain began manufacturing mirrors in 17th-century France, Louis XIV was on the throne. Today, its headquarters in Paris's business district oversees operations in more than 60 countries.

Saint-Gobain has always prized innovation – from its pioneering method of casting glass on metal tables to its embrace of float glass, low-E glazing and more. But no matter how it grows and changes, Saint-Gobain still has quality at its heart – and, of course, mirrors.

Like Pilkington, Saint-Gobain was a significant national supplier throughout the 20th century. In the 1980s, it was nationalised under the socialist Fifth Republic – one of 10 companies to be brought into public ownership.

Since being re-privatised in 1987, Saint-Gobain has expanded significantly. Today, it employs more than 180,000 people worldwide.

We look to Saint-Gobain for high-quality float glass that acts as a base for our toughened and laminated range. But it also produces low-carbon glass for commercial use, residential glazing and low-E glass.

In the UK, Saint-Gobain is based in Eggborough, North Yorkshire. There, its float glass facility boasts a state-of-the-art furnace. The results speak for themselves.

Conclusion

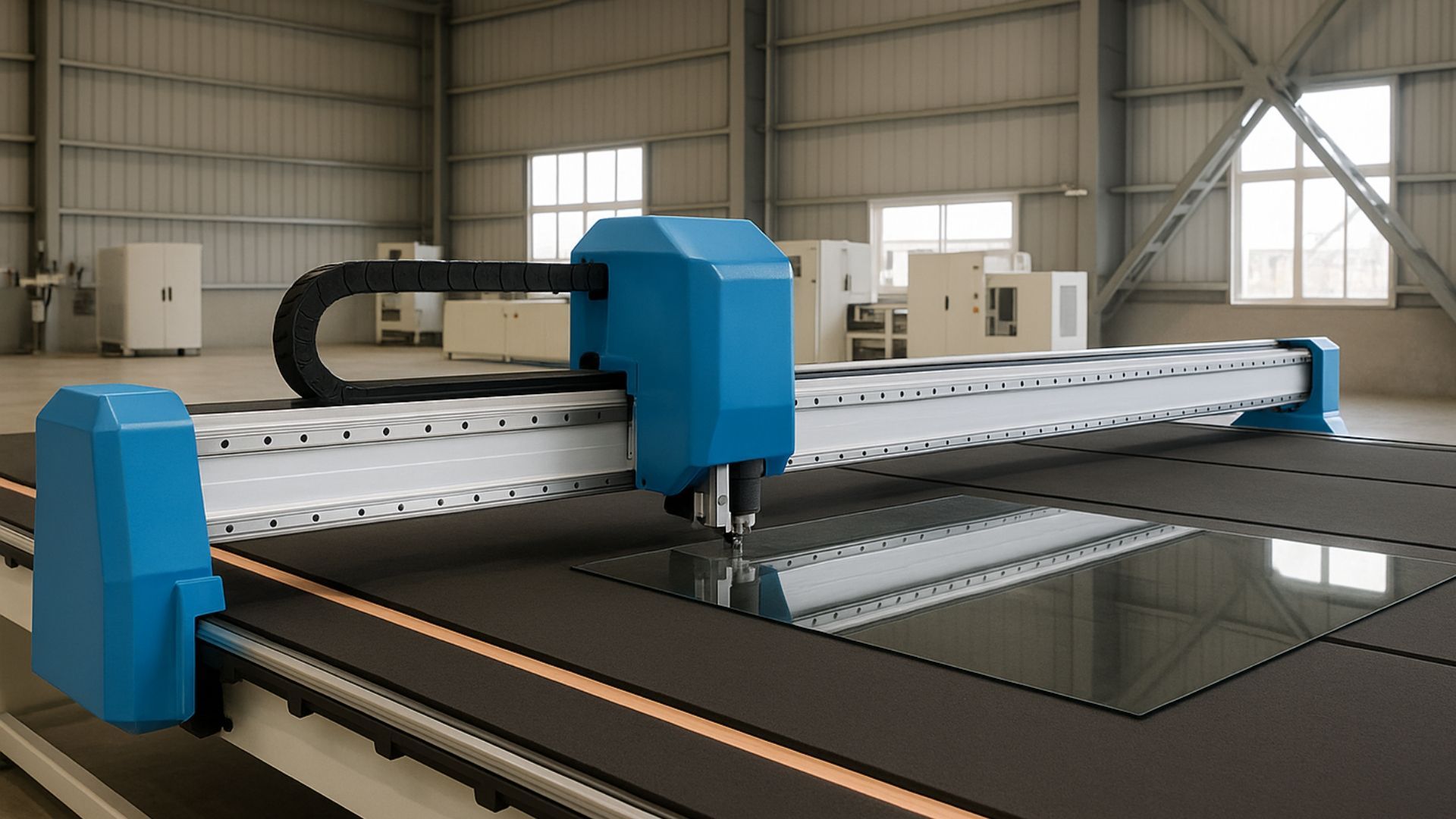

When looking for a glass processor, you need to be sure that it uses good-quality materials. No amount of expensive processing gear can turn bad glass into a high-quality final product. It's one of many reasons you can trust ToughGlaze: we always source from the best.

Are you looking for high-quality

toughened glass, cut to size? At ToughGlaze, we source our raw materials from only the best and cut, fire and treat them here at our state-of-the-art facilities.

Get in touch today for a quick, competitive quote.