How is security glass tested?

Share this blog:

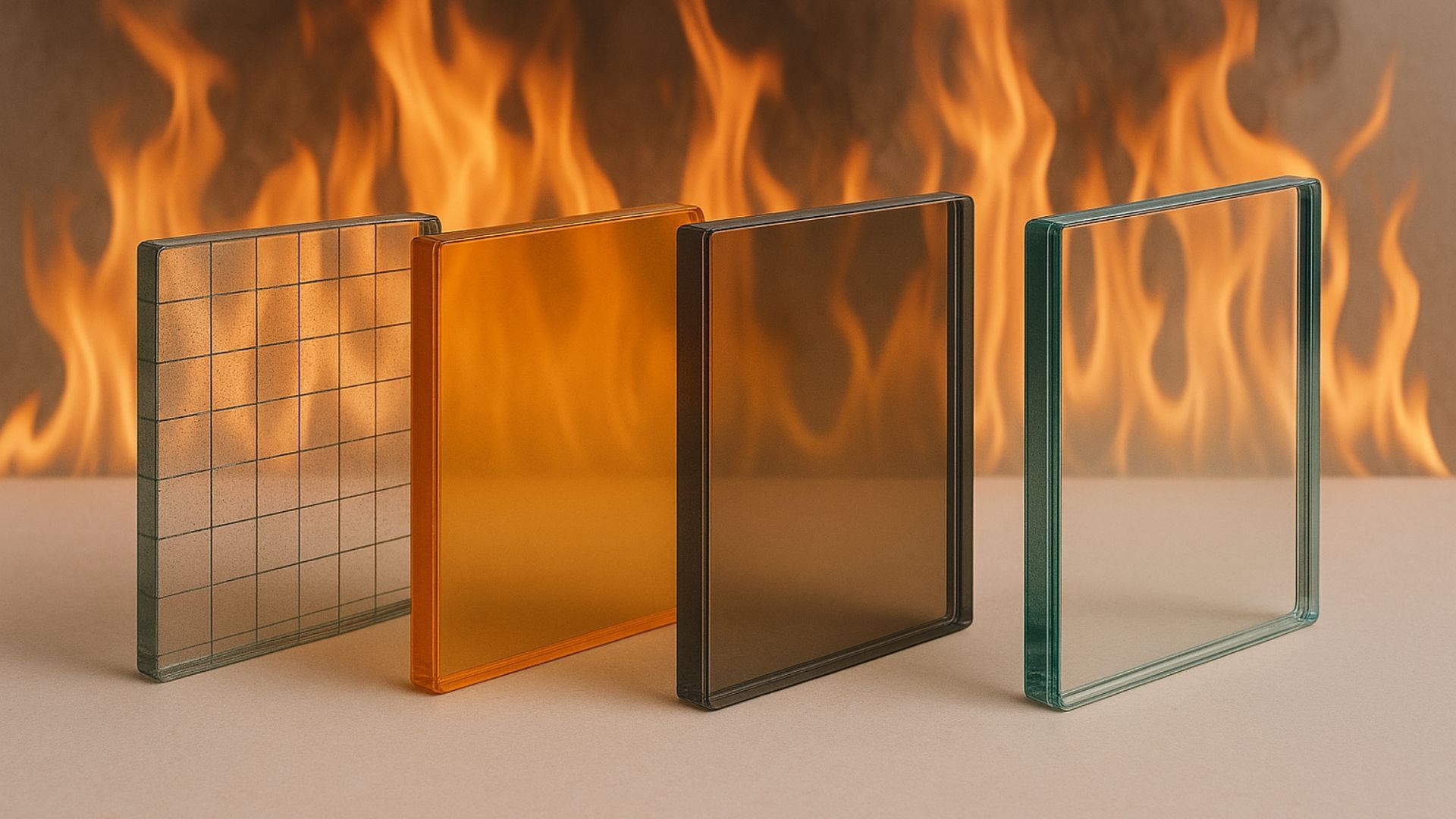

Different types of security glass can withstand bandits, bullets and bombs. Discover how they're tested.

For many applications, toughened glass will do the job just fine. But sometimes, you need glass that can withstand deliberate attack – whether from a weapon, a bullet or a bomb blast.

These types of security glass are laminated. Walk past any bus shelter after it's been vandalised and you'll see why. Bus shelters are made from toughened glass – and although they shatter more safely than standard glass, they still shatter, leaving an unprotected hole and hundreds of shards to clean up.

By contrast, laminated glass keeps its structural integrity, simply cracking like the side of an egg when you tap it with a spoon. It takes a

lot of effort to manually damage laminated glass. This means that in the event of a break-in, the assailant is dramatically slowed down.

But not just any old laminated glass will do. Security glass is manufactured specifically to meet the challenges posed by bandits, bullets and bombs. And when the product is ready, it has to be rigorously tested before going to market.

The reason is obvious. You can't sell a product that claims to withstand great force and then doesn't. That puts your customers and

their customers at risk.

Instead, security glass has to be tested to European standards and classifications. Before we look at these, let's explore the important distinction between safety glass and security glass.

What's the difference between safety glass and security glass?

Safety and security are the same thing, right? Well, yes and no. In the context of glass manufacturing and installation, they have quite separate meanings.

Both types of glass are there to reduce the possibility of break-ins, as well as injuries caused by flying fragments. But they are geared towards different types of threats.

Safety glass is there to reduce the risk of accidents when the glass is impacted, fractured or shattered by a human or by fire. Two industry-standard varieties are toughened glass and laminated glass.

How is bandit-resistant glass tested?

To qualify as bandit-resistant, glass has to meet EN 256:1999: "Glass in building – Security glazing – Testing and classification of resistance against manual attack". This standard is split into five classes: P1A up to P5A.

It consists of two tests: the hard body drop test and the axe test. Both of these test the degree to which the glass can withstand impact and break-through, as well as how well it protects against injury from cuts.

First, a 90-centimetre by 110-centimetre piece of glass is laid horizontally. Next, a steel ball (4.11 kilograms in weight and 100 millimetres in diameter) is dropped from varying heights onto the corners of a triangle in the centre of the glass. If the glass doesn't break, it passes the test, receiving its classification (P1A through P5A) depending on how many strikes it withstood and the height at which the ball was dropped.

The axe test, as the name suggests, measures the minimum number of strikes needed to create an opening. Between 30 and 50 strikes gives a classification of P6B. Fifty to 70 strikes, P7B. More than 70 strikes, P8B.

How is bullet-resistant glass tested?

Bullet-resistant glass should meet the EN 1063:1999 classifications. These run from BR1 to BR7 (handgun and rifle tests), then SG1 and SG2 (shotgun tests).

As with bandit-proof screens, the whole piece of glass has to withstand the blow or blows. This is achieved by layering up pieces of glass around an interlayer. These absorb the energy of the bullet and stop the glass from shattering.

Bullet-proof glass is tested under "worst case conditions" – in other words, it tests how the glass would withstand a bullet aimed squarely at it.

EN 1063 lets manufacturers offer spall and no-spall varieties of bullet-resistant glass. Spalls are those dangerous fragments that can sometimes fly off glass when hit with a bullet. This can cause injury even when the glass isn't breached.

No-spall bullet-resistant glass comes with an additional protective layer. When looking for a security glass manufacturer, check to see if there's a no-spall option available.

How is blast-resistant glass tested?

Blast-resistant glass is tested according to EN 13541:2000: "Glass in building – Security glazing – Testing and classification of resistance against explosion pressure".

The glass is subjected to a simulation of a high-explosive detonation. It's then awarded a classification between ER1 and ER4.

Like bullet-resistant glass, blast-resistant glass can come in spall and no-spall options.

If you're installing blast-resistant glass, you should seek specialist advice to ensure it's the right classification for the job.

What should you look for in security glass?

Before you buy any security glass, you should check that it's been tested in line with the appropriate regulations. But that's a bare minimum – not a compelling reason to choose one security glass product over another.

Instead, look for glass that's lightweight. Aside from anything else, a light piece of glass will come from a manufacturer that has sustainability in mind – after all, the thinner the product, the less carbon was emitted during its production.

Once you've found a provider that produces glass that's both lightweight and compliant with regulations, you should ask yourself whether it follows the building regulations surrounding security glazing. To take one example, will it resist the relevant wind and barrier loads?

Finally, you should consider whether you need your security glass to minimise sound. If so, investigate acoustic security glass. This has all the strength of security glass but lets in less ambient sound.

Conclusion

In some contexts, security glass is a must. But before you put your order in, make sure it meets the relevant requirements. That way, you can be sure it's good to go, protecting your customers, visitors and passersby.

Are you looking for an experienced, reliable

security glass manufacturer? Your search ends here.

Get in touch with ToughGlaze for a quick, competitive quote.