How glass breaks and why it matters

Share this blog:

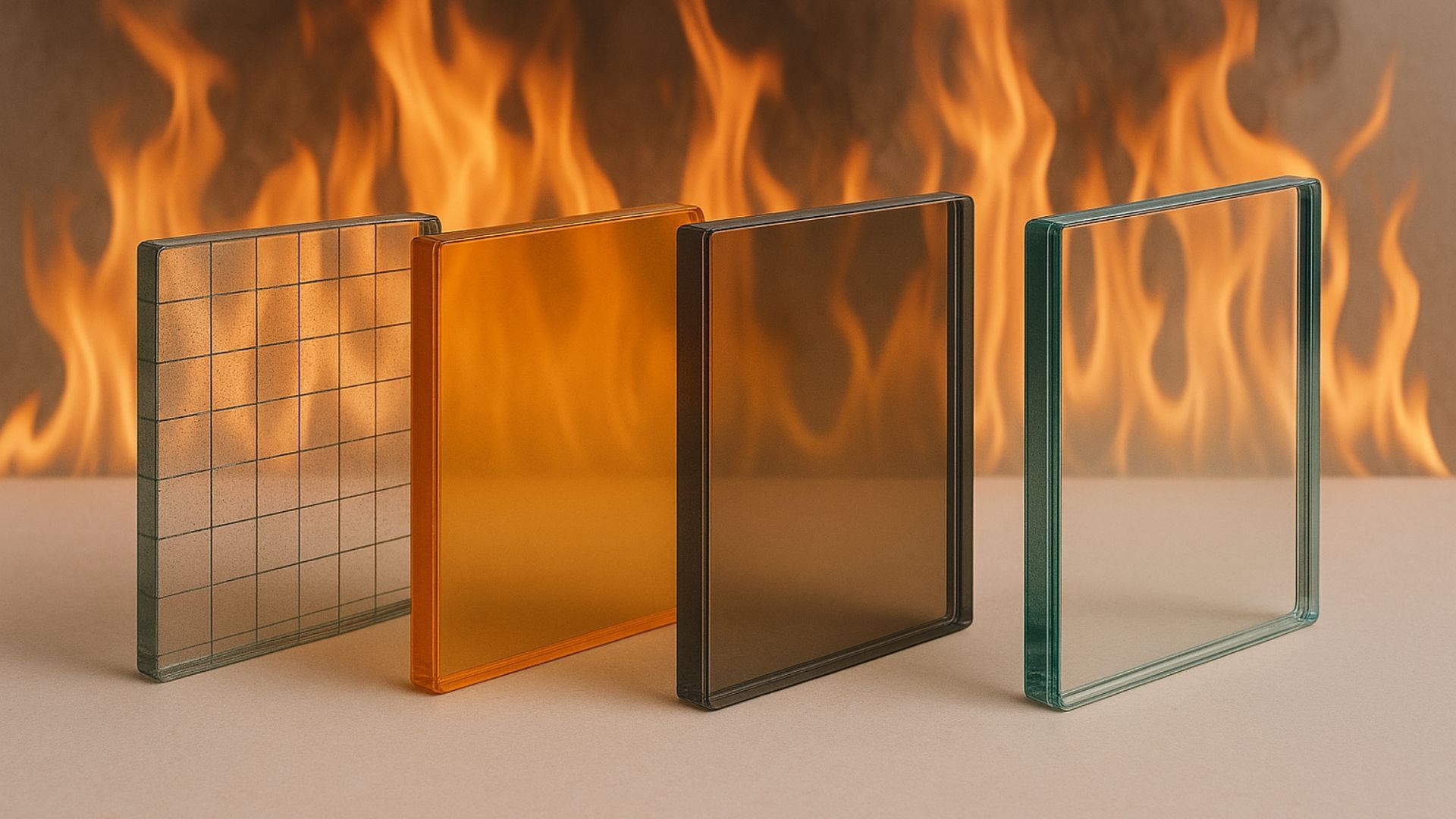

Different types of glass break in different ways. Find out how this can affect your choice of materials.

Like all structural materials, glass can break.

Sometimes, it's because of physical force – "bandits, bullets or bombs", as we say in the industry. Other times, it's because of thermal stress. Other times still, it's the result of manufacturing flaws or installation mistakes.

Whatever the reason, it's not something that any property owner (or installer) wants to happen. While there are ways to reduce the likelihood, the possibility can never be ruled out.

That's why the glass manufacturing industry has identified different types of breakage patterns for different types of glass. It means that certain types of glass can be installed in areas where breakage would be especially harmful to residents, visitors or passersby.

When planning a project, then, the thermal efficiency, strength and aesthetic of glass aren't the only considerations. You also need to consider how the glass would break.

Would it break into large, jagged chunks that could cause injury? Would it crack on the surface without leaving its frame? Or would it break into lots of small, harmless smithereens?

In this article, we take a look at how different types of glass break – and why that matters when it comes to choosing a type of glass for a job.

Annealed glass

Annealed glass is a standard kind of glass. It hasn't been specially treated or manufactured for safety. When it breaks, it breaks into shards. These shards can cause injury if installed in inappropriate locations.

It can break because of internal stresses brought on by a change of temperature and, unlike safety glass, it can break under relatively low impact. Knock a pane of glass by accident and it can, in theory, break.

Furthermore, poorly manufactured annealed glass can break spontaneously without any external force.

This presents safety risks. Annealed glass shards can cut people at the moment of breakage or leave hazardous remains on the floor.

This makes it unsuitable for most public-facing applications. If there's a chance that a passerby could be injured in the event of breakage, give annealed glass a miss.

Toughened glass

Toughened glass – also known as "tempered glass" – is a form of safety glass. When it breaks, it doesn't break into large shards like annealed glass. Instead, it shatters into lots of small, smooth smithereens.

This breakage pattern is a result of the manufacturing process. The glass is heated at a high temperature in a furnace and then cooled rapidly. This rapid cooling excites the molecules in such a way that it they set with high tensile strength. And when the glass breaks, this high tensile strength means it breaks into lots of little pieces.

Toughened glass is up to four times stronger than annealed glass. This makes it ideal for high-impact areas such as doors, shower screens and external facades.

Building regulations call for the use of toughened glass in particular areas. Its status as a form of safety glass doesn't mean it can't be made decorative. Toughened glass can be etched,

sandblasted,

digitally printed, coloured and more.

Heat-strengthened glass

Heat-strengthened glass is another form of thermally treated glass. It's about twice as strong as annealed glass but less strong than toughened glass. Because of this, it's not classed as safety glass.

It breaks like annealed glass into larger shards – but the chances of this happening are reduced by the manufacturing process.

This makes it suitable for high-strength applications where there's less risk of shattering. Skylights and balustrades, for example, are often made of heat-strengthened glass.

Laminated glass

Laminated glass is a super-tough form of safety glass. It's made out of two or more layers of glass bonded with an interlayer. This is typically made of polyvinyl butyral (PVB), but materials vary from product to product.

This sandwich-like construction means that laminated glass will never shatter. If you hit it repeatedly with a hammer, cracks will appear like a spider's web – but the polymer interlayer keeps the sandwich together like a very gluey jam.

As well as this structural strength, laminated glass provides greater sound insulation and UV protection than most other types of glass.

It's used when high levels of safety are required – car windscreens, for instance, and structural glazing such as glass walkways, balustrades, skylights and lifts.

Heat-strengthened laminated glass

As the name suggests, this type of glass combines the durability of heat-strengthened glass with the safety of laminated glass.

It's more resistant to changes in temperature and environmental stresses than other kinds of glass. For this reason, it's often used for structural features like glass curtain walls.

Toughened and heat soak tested laminated glass

Sometimes, but not often, toughened glass can shatter spontaneously. This is because of nickel sulfide inclusions.

These are tiny, pebble-like particles that enter the glass as a byproduct of the manufacturing process. They can be present in the glass for months or even years after installation.

Spontaneous breakage because of nickel sulfide inclusions is rare but far from unheard of. They can never be eliminated but the chances of spontaneous breakage can be dramatically reduced by a process known as heat soak testing.

This involves heating the glass at 290°C for several hours. Any panes that shatter in the furnace are replaced.

If you're concerned about nickel sulfide inclusions, you can always work with a glass processor that offers heat soak tested glass. This is an especially good idea if the glass will be installed in critical locations such as overhead glazing or high-rise buildings.

Stunt glass

Ever wondered how breaking glass effects are achieved in films and TV? The answer is stunt glass, also known as "breakaway glass".

There are several types. There's sugar glass: a combination of water, sugar, glucose and corn syrup. There are synthetic resins. And there's rubber glass: a catalysed silicone product.

All of these products enable directors to include breaking glass in their productions without putting cast or crew at risk. Clever stuff!

ToughGlaze supplies

laminated and

toughened glass panels to businesses across the UK and around the world. Thanks to our state-of-the-art glass processing facility, we can handle all things glass – all under one roof. Our services range from soundproofing to sandblasting and beyond. Don't hesitate to

get in touch for a quick, competitive quote.