How do they curve glass?

Share this blog:

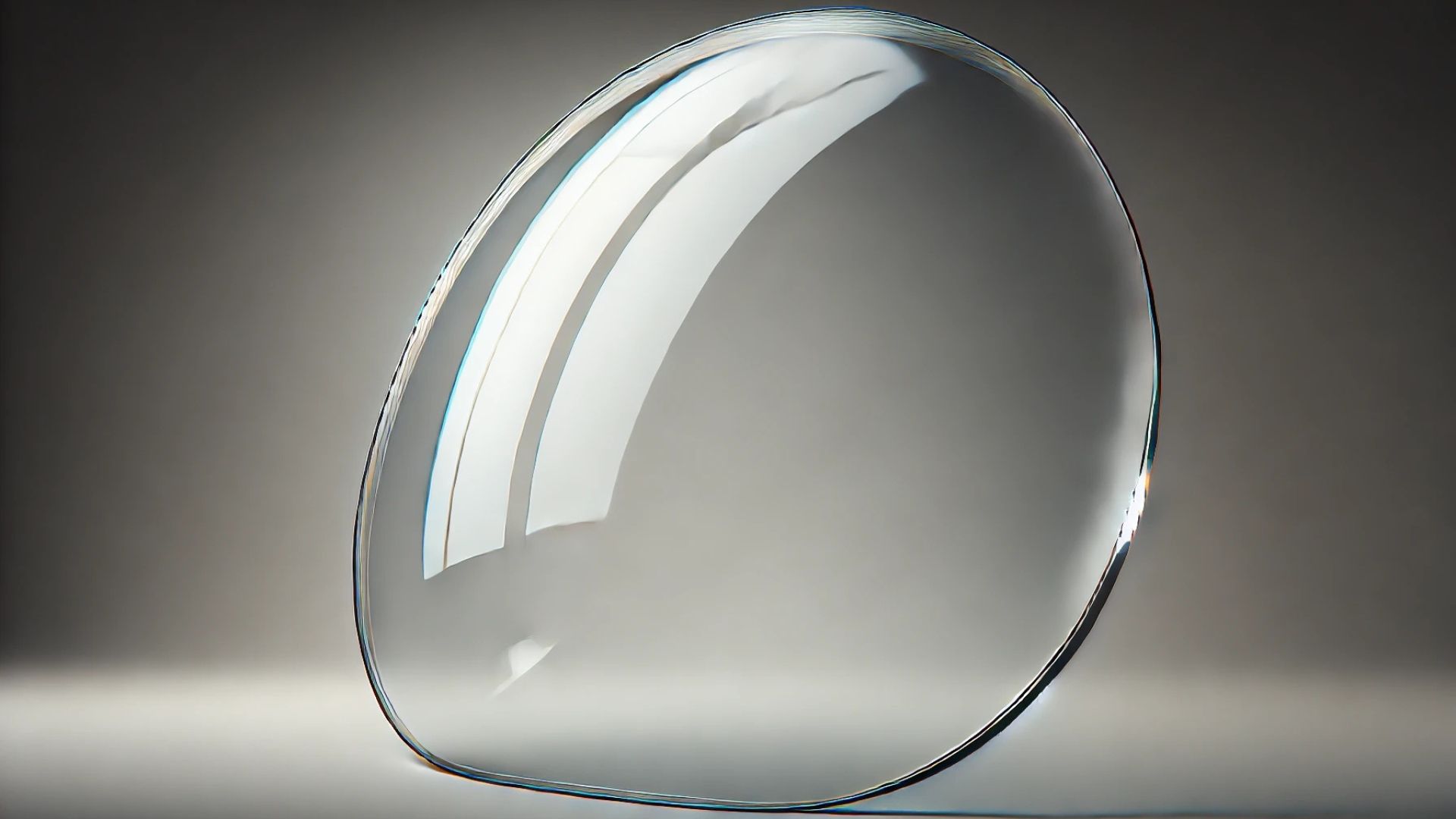

Curved glass is used in all manner of settings. But how is it made? Get to grips with the process in our guide.

Our world is full of objects – and people don't always know how they're made.

Take glass. Ask your average Jo how glass is made and she might mention glass blowers, furnaces and sand. But few could tell you the manufacturing process in any detail.

Yet glass is everywhere. Wherever in the world you are right now, you're reading this on a glass screen. You might be sitting by a glass window, drinking from, yep, a glass. None of this would be possible if it weren't for highly precise and specialised processes.

Of course, your average Jo isn't wrong. From one point of view,

glass is just sand plus heat – a lot of heat, sure, but heat nonetheless. Industrial glass, however, is made from sand and other materials measured out in precise quantities.

That's before you get into the world of

laminated glass,

toughened glass or the topic of today's article: curved glass.

Common sense will tell you that if you try to bend or curve a pane of glass, it will break. Yet bent glass has been used in architecture since the early 19th century – and today it's everywhere.

Despite its Victorian origins, curved or bent glass didn't become generally available until the 1990s. This was made possible by the development of the first horizontal tempering machine with a bending furnace.

So, how is it made, exactly? The answer involves a furnace, a mould and a heck of a lot of heat.

How is curved glass made?

When it was invented in the late 19th century, curved glass was very expensive. Even today, it comes at a cost. That's because precision is the order of the day.

This is true of all types of glass, sure. But with curved glass, the slightest difference in details can spell disaster for the finished product.

It takes time – but above all it takes skill. (Look, we don't need to tell you, but don't try this at home.)

First, the sheet of glass that's going to be curved is cut to size. This in itself is a job requiring surgical precision. Whether the glass processor uses a manual blade or a cutting machine, just the right amount of pressure is required.

Next, the glass must be cleaned. This is because dust and impurities can lead the glass to crack or shatter. This isn't something a glass processor can afford to get wrong.

The glass is checked with a UV lamp. This shows up any specks that are invisible to the naked eye. The glass is then cleaned and polished.

Next, a steel mould is constructed. This is shaped to match the radius and dimensions of the curve.

At this point, you might be wondering why glass in a furnace doesn't stick to the mould. To stop this happening, the glass is covered with a mixture of detergent and calcium carbonate.

Applying this mixture isn't so different from greasing a baking tray – but unlike making a split tin loaf, a failed piece of curved glass will cost you.

The glass is now placed inside the mould and loaded into the furnace. It's turned up to around 700°C (1,292°F) – hot enough to melt the glass so it starts to take on the shape of the mould.

The glass should now be curved. However, before it's removed from the factory, it needs to be cooled. This is a gradual process that can take a couple of hours or more.

By now, it should be apparent why curved glass is often more expensive than flat glass. One word for you: moulds.

Sheets of glass can be made in large numbers with the same process over and over again. They can then be cut to size. But if you want a piece of curved glass for your building, a bespoke mould will have to be created. This adds a stage of complexity to the process that ends up on your bill.

Some types of curved glass – windscreens, for instance – can be produced en masse. But customised curved glass is a bespoke process that's for special occasions only.

What is it used for?

Curved glass is a surprisingly versatile product. In architecture, it can be found in balustrades, balconies, revolving doors, staircases, partitions and more.

Fish swim in curved tanks. Some smartphone screens are curved for effect. Windscreens, coffee tables, shower screens… the list goes on. And on. And on.

One notable example of curved glass in art is the American artist Edward Hopper's 1942 painting

Nighthawks.

This classic artwork shows four people having a late dinner in a downtown diner.

It's not obvious on first viewing, but once you've clocked it you can't miss it. That iconic window is curved!

Is curved glass tougher than flat glass?

Curved glass is often tougher than flat glass. This is a direct result of the bending process. The use of a mould creates a shell-like structure that's more resistant to bending than flat glass.

Curved glass can also be toughened or laminated for extra toughness. These types of glass are varieties of safety glass – a type of glass that's designed to break safely and can be built to withstand manual attack, extreme weather and even bullets.

Toughened glass, for instance, is more than five times stronger than standard annealed glass – and that goes for curved glass, too. When it breaks, it shatters into lots of tiny, harmless pieces rather than jagged shards.

Laminated glass, meanwhile, maintains its structural stability even when dealt a hefty blow. Formed of two panes of glass with a plastic interlayer, it breaks without shattering. The outer pane cracks in a spider's web pattern while staying in its frame.

Do you need curved glass for a project? At ToughGlaze, we do everything glass – including toughening, laminating and, yes, curving. Talk to our

commercial glass specialists today for a quick, competitive quote.