A guide to glass edgework

Share this blog:

Good-quality glass can be enhanced by good-quality edgework. Learn all about it in our handy guide.

How can you tell if a piece of glass is good-quality?

It's partly to do with performance. Good-quality glass keeps the heat in. It keeps sound out. It's tough. It's clear. It's durable.

But all of these positive attributes take time to notice. There's actually a much quicker way to assess the quality of glass: look at the edges.

If a pane of glass was delivered to you straight out of the factory, its edges would be dangerously sharp. For this reason, glass is usually sanded before hitting the market.

A sanded edge is known as a "seamed" edge. This will get rid of any sharp points – but it may leave in place some blemishes and bumps.

Seamed glass is safe but not seamless. This makes it suitable for frames, where the edges are hidden.

But if the edges are exposed, you need edgework, not just a seamed edge. "Edgework" refers to the methods used to make edges smooth, shaped and super-safe. It creates a decorative profile, minimises flaws and even adds a little strength.

The market is filled with different types of edgework. Three of the most common are flat polish, pencil polish and bevelled edge.

In this article, we look at these three types of edgework and where they can be applied.

1. Flat polish

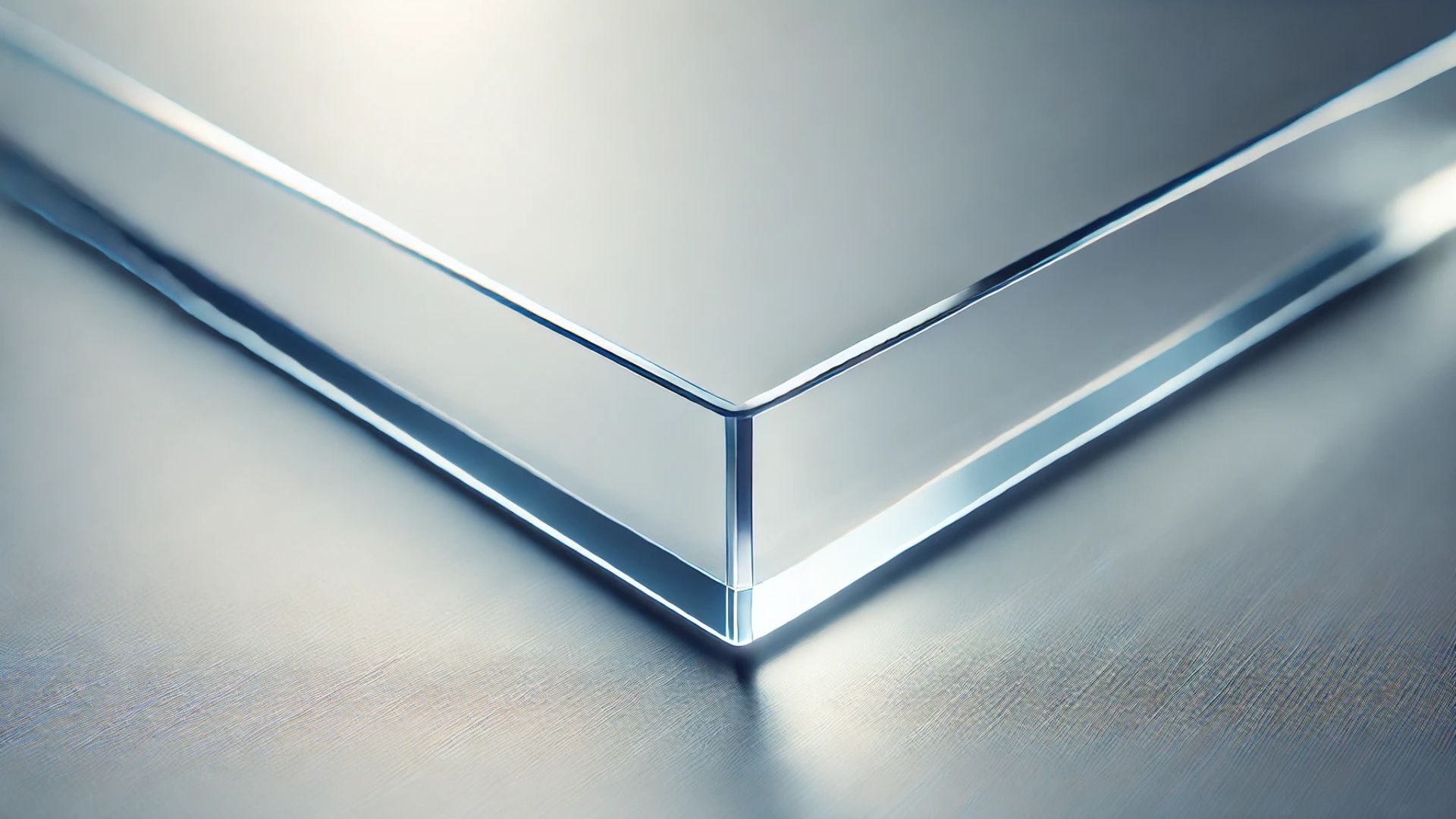

Flat polish edgework gives glass a flat, precise edge. It's a contemporary look that can be seen all over the place. It's extremely popular for bathroom mirrors, tabletops, display cases and frameless bathroom cabinets.

Characterised by clean and clear edges, flat polished glass is all about smoothness. The glass is run through a machine with a belt that files off any unwanted glass chips and smooths out the edges.

2. Pencil polish

Pencil polish edgework comes under many different names: crown edge, semi-round edge, half-moon edge and diamond edge, to name but a few.

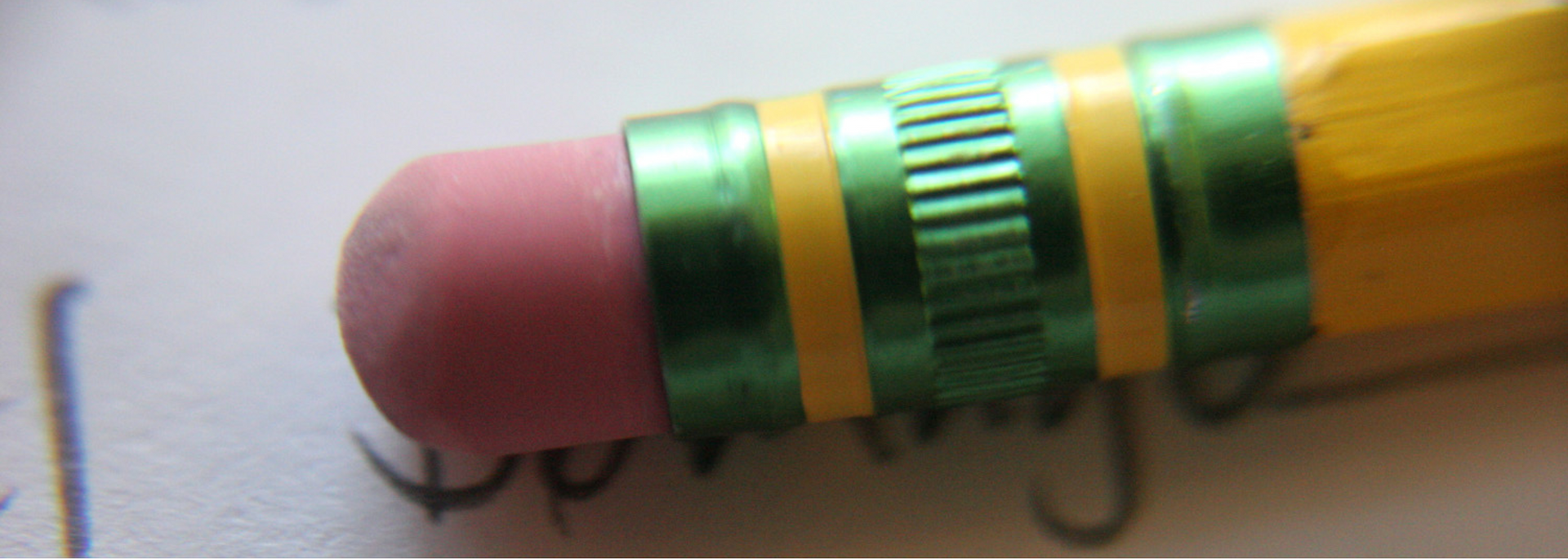

Whatever it's called, pencil polish glass has clear, rounded corners that resemble the edges of a pencil eraser.

All good-quality edgework is safe. But if you want that extra bit of safety, pencil polish glass can be a good shout. That's because its rounded edges all but remove the possibility of getting cut.

It's a popular option that can be seen in glass shelves, circular tabletops, car door windows and much more besides.

3. Bevelled edge

Bevelled edges are the most obviously elegant or aesthetically attractive of these three types of edgework. They're created by grinding and polishing the edges of the glass at 45 degree angles.

You've almost certainly seen bevelled mirror glass, where the glass is shaped so it looks a little like an in-built frame. It's used for both framed and frameless mirrors, as well as tabletops, windows, shower doors and insulated glass units (IGUs).

Bevelled edgework is created by grinding the glass with multiple wheels. The edges can be cut and polished to precise angles for a more customised look.

Other types of edgework

We mentioned that these are three of the most common types. But there are plenty more available for the discerning glass buyer.

You may see "ogee edges" advertised. An ogee edge is a double edge – one concave curve followed by a convex curve. Its main function is to decorate. For this reason, it's often found in glass furniture and decorative panels.

Then there are bullnose edges – another kind of smooth, rounded edge. This type of edge can often be seen on countertops, stair treads and handrails.

Can toughened glass have edgework?

Yes! One of the many great advantages of toughened glass is that it opens up many possibilities for customisation and decoration. Edgework is a strong example of this.

Glass is toughened in a furnace at a very high temperature. Once out of the oven, it can't be cut, ground or etched. For this reason, edgework has to be applied before the toughening process begins.

Toughened glass – also known as tempered glass – is a strong, durable, versatile product that's a staple in domestic and commercial installations. Getting toughened glass with elegant edgework lets you combine high functionality with aesthetic appeal.

Edged toughened glass is also a sign of quality. Done badly, edgework can break during the toughening process. This means toughened glass with any kind of edgework shows an attention to detail and command of the toughening process.

What type of edgework should I use?

Projects of all kinds require a decision to be made about edgework. Whether you're ordering a custom-made mirror or the panels for a full office refurb, you need to know what you're asking for.

The main consideration is aesthetic. After all, any glass processor worth its salt will provide you with glass that's safe and suitable. The question is: what effect do you want and how will it blend in with the rest of the project?

We've talked you through some of the most common styles of edgework. One thing to bear in mind, however, is that different providers use different names. Sometimes, the differences are subtle. Other times, they're significant.

So, if you know what you want but don't know what it's called, no sweat. Just tell your supplier what you're after and they'll be able to explain your options.

In fact, this is a good rule of thumb for interactions with your glass processor in general. If you know what you want but don't know the technical details, just ask. An experienced and reputable processor will always go the extra mile to help you realise your design dream.

So, whether you go for flat polish, pencil polish, bevelled edges or something else entirely, we hope you get the right glass for the job.

Are you in the market for high-quality

toughened glass panels – with professional edgework to boot?

Get in touch with ToughGlaze today for a quick, competitive quote.