Why does toughened glass shatter into small pieces?

Share this blog:

Toughened glass shatters into small pieces rather than large shards. Find out why in this 5-minute guide.

In Melbourne, Australia, ICI House has stood for more than six decades.

When it opened in 1958, the ICI House was the talk of the town. It wasn't just that it was Australia's first skyscraper. It was also a forerunner of the way we live now.

ICI House was a forerunner of modern workplaces with its range of onsite amenities. After all, getting an espresso on the 18th floor and taking it to the games room at break time was hardly the norm in the late 1950s.

However, the ICI House ran into difficulties. In 1960, a glass pane shattered mysteriously and unexpectedly. People were so perplexed by this spontaneous breakage that they surmised it must have been a sniper attack.

Sadly, it wasn't an isolated incident. More panes shattered and fell – enough for the building to be nicknamed the "deciduous building".

Glass breaks. But why would it break spontaneously like this? And why does it break into smaller pieces rather than large shards?

To answer that question, we have to look into the manufacturing process.

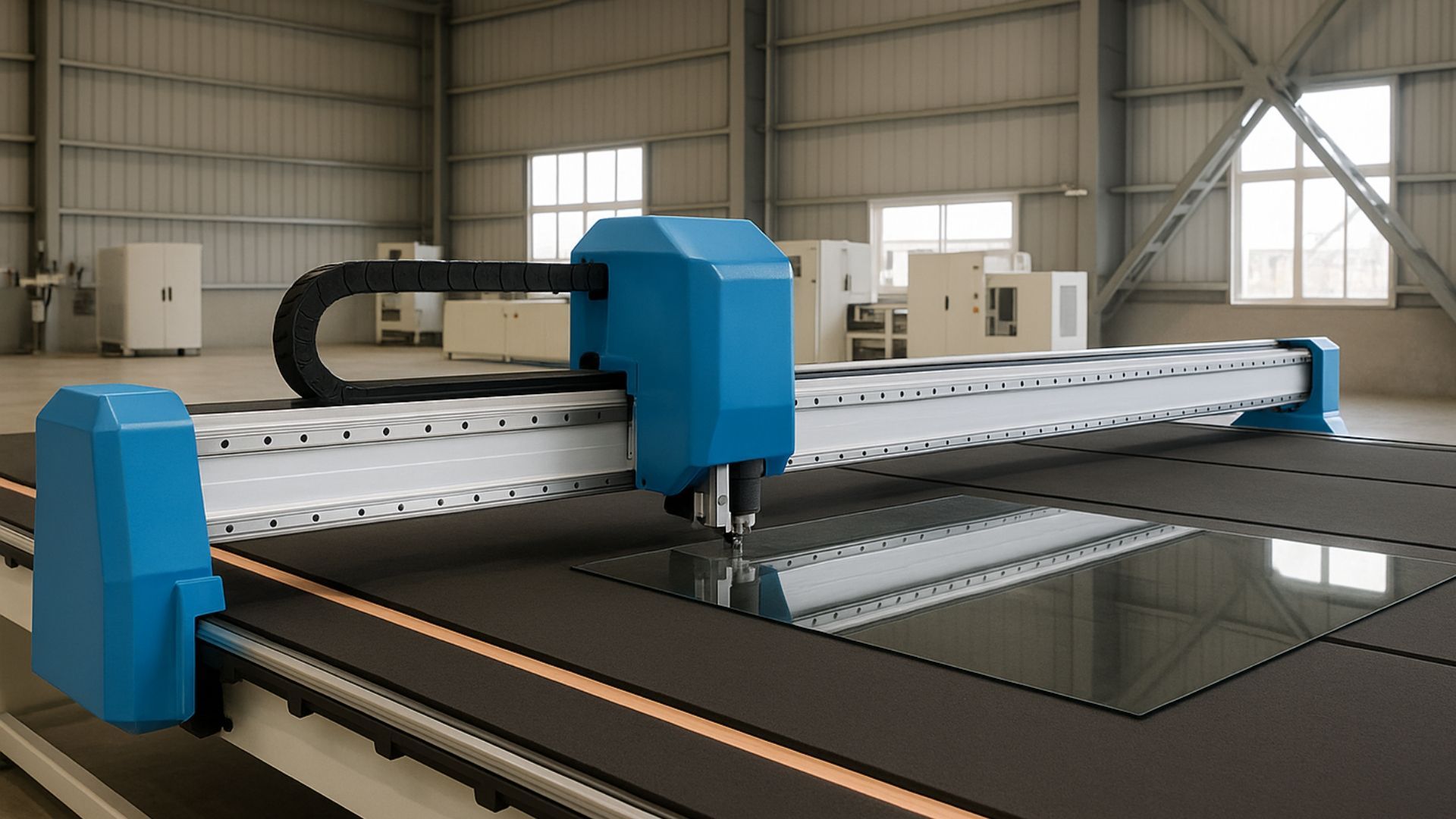

How is toughened glass manufactured?

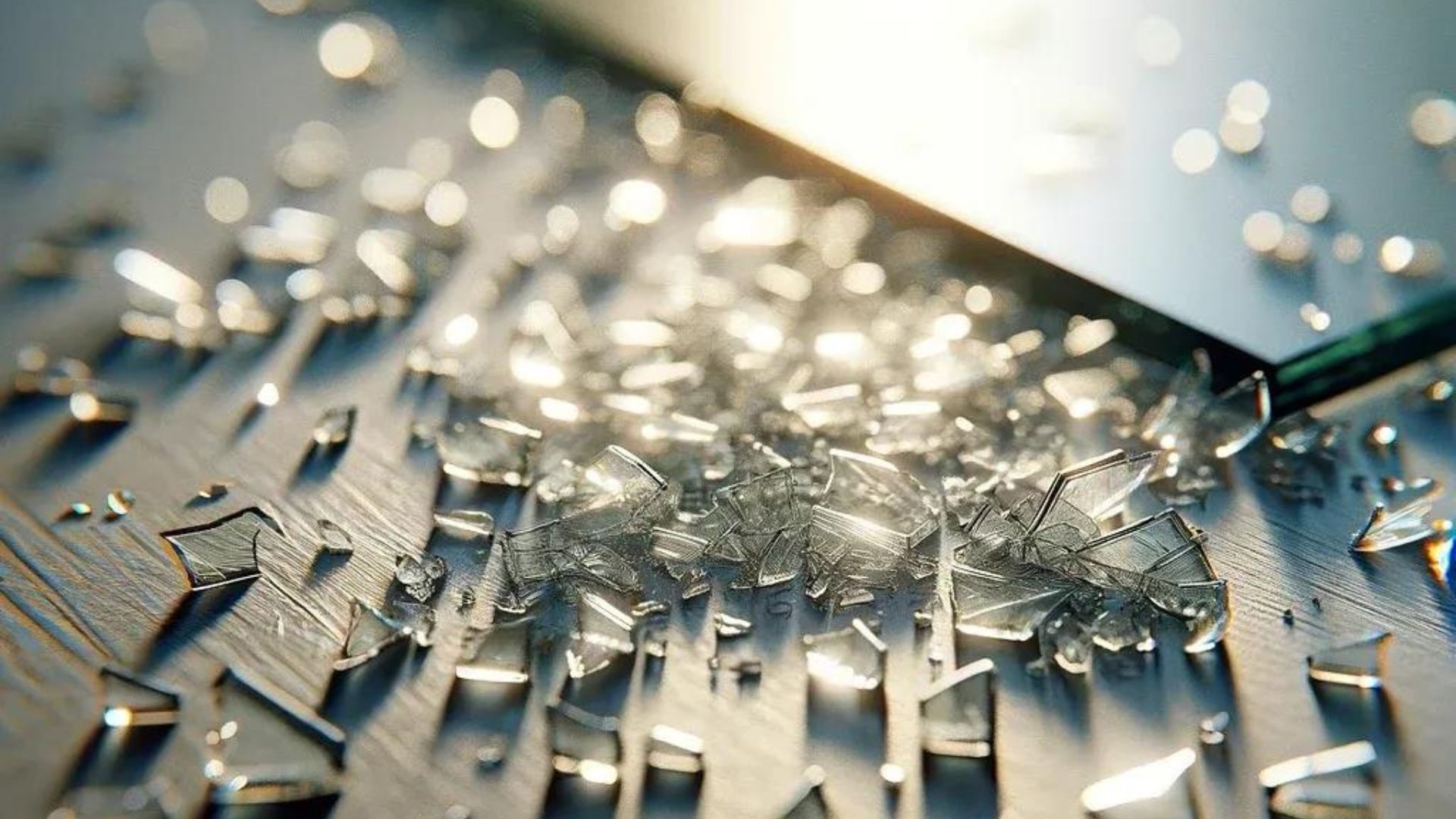

Toughened glass is a form of safety glass. In the event of breakage, it shatters into small, semi-round pieces. This means bystanders are less likely to be injured than if the glass broke into shards.

This is a result of the manufacturing process. The glass panes are placed in a super-hot furnace. Once heated, they're rapidly cooled to room temperature.

This cooling process is integral to the properties of toughened glass. Cooling takes place much faster at the centre of the glass than at the surface. This causes what's known as "compressive stress" at the surface and "contraction and tensile stress" at the centre.

The compressive stress gives the toughened glass its increased strength. The higher the stress, the smaller the pieces that the glass will break into.

The benefit of this differential heating is that it makes the glass more robust. A manufacturer can now stretch or pull the glass to a certain limit without it breaking.

Next, the toughened glass is treated with hydrochloric acid. This gets rid of any scratches on the surface and increases its strength.

It's this manufacturing process that leads toughened glass to break into tiny, granular pieces. These pieces interlock with neighbouring pieces, making them less likely to fall.

Why does toughened glass spontaneously break?

Before we go any further, it's important to say that the chances of toughened glass spontaneously breaking are low. But that doesn't mean it's something that you as a project manager, installer or supplier shouldn't keep in mind and work to mitigate.

Most of the time, toughened glass will only shatter if subjected to significant force. The only way to stop this from happening is through on-premises security. It's not something that you can rule out just because you bought high-quality glass.

Spontaneous breakage, however, is something that can happen if heat soak testing is skipped. This is an important part of the manufacturing process – but not all glass processors do it.

Let's take a look at what it does and why it's so important for your glass supplies.

What is heat soak testing?

We've seen that toughened glass is strong because of compression. The heating and cooling process results in a pane of glass with a sturdy outer layer and a tensile inner region.

Sometimes, unwanted inclusions can appear in the inner, tensile region during the manufacturing process. One of these is nickel sulphide – a pesky intruder that's been called the "Trojan Horse of glazing".

If undetected, nickel sulphide can grow over time and eventually cause fractures. The worst-case scenario is that a fracture will cause the pane of glass to suddenly shatter.

Not all panes of toughened glass contain nickel sulphide inclusions – and not all panes of glass with these inclusions spontaneously break. However, it's important to get your glass from a firm that's taken precautions in the form of

heat soak testing.

This is where the newly toughened glass is heated at a very high temperature. If it cracks, the pane is discarded. This process is repeated to find out which panes of glass in the batch are fit for purpose and which should be replaced.

Why is heat soak testing important?

If you're an installer or project manager sourcing materials, you might think that heat soak testing is an optional add-on that's just not worth it.

But while spontaneous breakage is rare, it's not unheard of. If it happens to you, you not only put your staff and visitors at risk – you also have to pay the price, literally.

For this reason, we strongly recommend working with a firm like ours – one that offers heat soak testing as an integrated part of the manufacturing process.

How is toughened glass different from laminated glass?

Both toughened and laminated glass fall under the umbrella of safety glass. However, they have different breakage patterns thanks to the different ways they're manufactured.

If you hit a sheet of laminated glass with a hammer, it's unlikely to break at all. If the force is strong enough, it will cause a "spider's-web" breakage but won't shatter.

This is because laminated glass is made from two sheets of glass that are held together by a plastic interlayer sandwiched between them. Its robustness makes it ideal for windscreens, security glass and structural glazing.

Conclusion

Toughened glass is built for safety – and the way it shatters reflects this. Rather than breaking into large, dangerous chunks, it shatters into small pieces, reducing the chances of injury.

If you're looking for toughened glass, make sure you work with a processor or supplier that offers heat soak testing. It's an extra layer of security to make your safety glass ultra-safe.

In the market for

heat-soaked toughened glass? Don't hesitate to

get in touch for a quick, competitive quote.